|

|

This is a slightly edited and web-friendly version of the Thesis submitted at Clarkson University in partial requirements for the author’s MS in Electrical Engineering. It is available here as a resource to those interested in learning about anaerobic digesters and their control systems. The online version omits some of the figures and appendices of the print version. A full version of the thesis is available as a PDF file here . For questions, feel free to contact Greg Linder, greg.linder@gmail.com. This document is hosted as part of many other projects by Greg, more available at at linderlabs.com's innovations section.

I would like to thank my family, my fellow Clarkson students, the Clarkson Golden Knotes, and all the faculty and staff at Clarkson University for their continued support. Specifically, thanks to Dr. Stefan Grimberg, Dr. Sue Powers, Dr. Eric Thacher, Dr. Thomas Ortmeyer, and Jill and Donna in the ECE office.

Funding for this research was provided by the NY Agricultural and Market (grant C010669), DOE (grant number DE-FG36-06G086007), USDA CSREES (grant number 68-3A75-6-512) and NYSERDA (#7848). Publication of these results does not imply endorsement of the findings by either of these agencies.

The earliest documented scientific study of biogas was presented in 1648, when Jan Baptist van Helmont described “spirits. . .coagulated after the manner of a body, and is stirred up by an attained ferment” [1]. Throughout developing countries, small scale home-use digesters are widely used for producing gas for cooking. China, for example, has 7,000,000 small scale digesters serving 4% of the population [2]. This equipment is very simple, consisting of nothing more than a covered pit and a length of pipe, with a bucket of water to act as a pressure regulator.

Systems of this sort are not directly applicable to the diverse needs of the United State’s agricultural industry. A small farm digester in India may be capable of dealing with the waste of just a few cows. These digesters often have very long residence times and require frequent cleaning. In order to scale up operations to the United State’s Confined Animal Feeding Operations (CAFO), where thousands of animals may be generating concentrated waste streams, more technically advanced systems are required. The United States Environmental Protection Agency (EPA) specifies CAFOs in terms of size. For dairy operations, a “Small CAFO” is less than 200, a “Medium CAFO” is between 200 and 699, and for a “Large CAFO” means 700 or more mature dairy cattle [3].

According to the AgSTAR program, sponsored by the Environmental Protection Agency (EPA), the United States has over 700 MW worth of electrical generating capacity available from anaerobic digesters distributed around the country whose fuel supply constitutes only hog and dairy cow manures in operations classified as medium to large CAFOs [4]. To illustrate the potential monetary value of this resource, consider the 750 MW expansion project of a large coal fired power station near Pueblo, Colorado. The Comanche 3 plant, scheduled to go online in August, 2009 has an estimated initial capital cost of 1.3 billion dollars [5]. This illustrates the amount of money utilities are willing to pay for centralized base load power.

Although the digesters exploiting animal manure would be distributed throughout the United States, the monetary value of the electrical power they could produce is nonetheless significant. According to the Energy Information Administration, in 2006 the average wholesale price of electricity in the United States was $53.00 per megawatt-hour [6]. Assuming the digesters installed in the United States can reliably operate 90% of the time that amounts to over $290 million worth of electricity per year at wholesale prices. Local farm use is even more valuable. As of 2006, the average retail price of electricity in the United States was around $89 per megawatt-hour, for a savings to farmers of $490 million per year over buying electricity at retail rates [7]. According to data presented in Chapter 6, a digester-equipped 500 cow dairy operation in New York State could save a farmer nearly $73,000 per year in utility costs. Such savings could be of great value to agribusiness in the United States, if digesters could be made both inexpensive enough and sufficiently reliable to meet the demanding needs of farmers.

The key barriers to wide-scale adoption of this resource are concerns about the capital costs and associated maintenance issues. Evidence from digesters installed in the United States shows that these concerns are valid, as demonstrated by the fact that traditionally 50% of US digesters failed soon after completion [8]. Typically, if farmers were interested in running a digester the machines succeeded if their owners were able to perform regular maintenance on equipment before small problems developed into major situations. The fact is that farmers are nervous about installing this equipment. A survey of New York state dairy operations found that 87% of farmers felt that digesters being “Very expensive to install” was a concern. Additionally, approximately 30% of farmers surveyed reported “Generator engine failures”, “Pump failures”, and “Require a lot of labor time to operate” as concerns associated with digesters [9]. The experience with Sheland Farms supports the survey’s findings, as the system owner there reports at least 20 minutes a day on digester maintenance work, reaching up to several hours when equipment failures occur [10]. There are some cases of digesters even going unfixed because the installers went out of business, making it impossible for farmers to get spare parts and service [11].

However, digesters, being small-scale power plants, are capable of being remotely controlled and monitored utilizing modern control and communications protocols. These modern protocols, and the practice of using them for local load and generation control, is a burgeoning segment of “smart grid” technologies. Furthermore, once remote control and monitoring has been demonstrated and installed, the offloading of care and maintenance of the digester to an off-site service provider would be a very effective tool both in decreasing costs of operation and decreasing the perception of digesters as unreliable. Furthermore, the application of standard utility protocols to digester control would foster a growth in small companies providing digester support services, which could be a financial benefit to small rural communities.

Pursuant to the goal of deploying remote monitoring and control systems to lower digester maintenance costs and improve reliability, the author presents two years worth of projects culminating in an in-depth discussion of a low cost and highly reliable utility-standards based communications system which can be used for remote digester management. In order to provide the context for the control protocols presented, a pilot digester was employed which required the development of a reliable local digester control system. Additionally, data was gathered on failures of a commercially installed digester located in New York State, to understand the needs of a communications link on a digester, and the current shortcomings of deployed systems.

The first chapter is an overview of common waste-to-energy technologies and a discussion of the scale of anaerobic power available in the state of New York. Chapter 2 describes the Clarkson anaerobic digester pilot plants, including introductory discussions of the author-designed systems, including those for control, manure, biogas, heating, and mechanical support.

Chapter 3 offers an in depth analysis of the Clarkson anaerobic digester pilot plant’s author-designed and built control system, including presentations on both hardware and firmware. Chapter 4 presents the electrical loads of the pilot plant, organized by system and time, and clearly illustrating the shortcomings of time-based polling for load assessment. Chapter 5 presents failures associated with the pilot scale plant, their causes and data acquisition requirements to remotely diagnose the failures. Chapter 6 discusses generator outages of a full scale digester, included illustrations of how lack of a real-time telemetry link caused increased downtime.

Having established a baseline of standard failure modes and the basic channels requiring monitoring to detect and address these failures, Chapter 7 discusses the basics of smart grid technologies, and how they may be employed to gather the data required to diagnose the situations established in the first five chapters. Chapter 8 presents a brief discussion of the per failure bandwidth requirements of the anaerobic digester. Chapter 9 offers a discussion of the types of failures addressed easily via the remote SCADA link vs. those which are only addressable by local operators. Finally, the last chapter contains a conclusion. As an added feature, Chapter 11 includes an overview of design lessons learned by the author through debugging two and fully constructing one portable anaerobic digester, as well as full plumbing diagrams, electrical diagrams, and control system functional block diagrams of the Clarkson digester controller.

According the the EPA, a farm qualifies as a Confined Animal Feeding Operation (CAFO) if the animals are maintained indoors for more than 45 days out of any 12 month period and there is no sustained vegetation in the confinement area [12]. For the size of farm appropriate for digester use, this concentration of animals requires that systems be in place to manage the waste stream as a point source of pollution [13]. In the case of New York State, all dairy farms with over 200 cows are treated as CAFO farms, requiring a comprehensive manure management plan compliant with the Natural Resource Conservation Service (NRCS) NY313 Standard [14]. As a general rule, for every gallon of milk produced, three gallons of manure are produced by a dairy farm [15].

As an example of the volume of waste generated by a multi-hundred cow dairy operation, consider one Haubenschild Farms, a large Midwestern dairy. Their cattle produce around 27 gallons of manure slurry per day per cow, with a range between 15 and 30 gallons per day depending primarily on whether or not the cows are lactating [16]. Using approximately 500 milking cows for a baseline anaerobic digester and assuming 30 gallons per day amounts to around 15,000 gallons of manure slurry per day. Manure slurry includes cow manure, bedding material, and anything else that happens to be collected in the barn manure collection system. Key characteristics of common dairy manure, as found in sand-bedded dairies in northern New York State, is presented in Table. 1.1 [17].

|

Dealing with this amount and type of material poses a challenge for any dairy operation. Additionally, manure poses a great deal of smell and mess which may can cause aroma issues for surrounding neighborhoods. What follows is an overview of four currently valid technologies for dealing with farm waste streams. All of these technologies require some sort of front-end manure handling systems. The complexity of these systems could be as simple as a mechanized front end loader to scope up manure into a pile, or as advanced as systems to separate sand and solids for various further pre-processing. The following sections are meant to be a general overview of current manure handling practice.

The most common method to dispose of dairy manure is spreading the material on arable land in order to return nutrients to the soil [18]. This is done as part of a larger Comprehensive Nutrient Management Plan (CNMP), which includes considerations for water runoff, commercial fertilizer application, and other soil and environmental issues [19]. In order to implement these plans, farmers will often store manure in lagoons for varying periods of time. These lagoons may provide up to six months of storage or down to just a few days, depending on the herd size and the CNMP [20].

While the CNMP can deal with excess nutrients and groundwater runoff, there are other issues associated with spreading raw manure. Perhaps the most obvious to those who live in dairy country is the odor from dairy operations which can be exacerbated by spreading [?]. However, in addition the the obvious odor, raw manure spreading also introduces numerous pathogens into the environment including protozoans, bacteria, and enteric viruses [22]. An effective animal manure handling system must therefore deal with both nutrient release to the land and human health issues. No matter what sorts of steps are taken to deal with environmental and pathogenic issues relating to manure, the volume of material still ends up being returned to either the land or air in some manner.

In the following sections, the processes are ranked in order of moisture content, from lowest moisture content at time of use (direct combustion), to highest (anaerobic digester).

Direct combustion of animal manure has been used since antiquity as a building material and cooking and heating fuel [23]. Even today, one former member of the Clarkson Biomass group has immediate friends and family in Africa who commonly use animal manure for heat and as a construction material [24]. In this application, the cow manure is simply left in the field until sufficiently sun baked, and then brought in and lit on fire, where it burns slowly with an even flame.

In the United States using manure for construction and cooking fuel is not necessarily a valid option. However, despite this, there is at least one vendor who offers a farm-scale direct combustion system for getting rid of manure. With the Skill Associates Elimanure system, the solid component of the manure is separated, dried, and burned in a boiler to generate steam to run a turbine [25]. The steam from the generating plant is used as a heat source to dry the incoming manure prior to burning [26]. An example of this system was installed at a farm producing 2,200 dry pounds of manure per hour from 4,000 animal units, which when burned provides enough steam to run a 600 kW generator [27].

For sufficiently dry manure such as those produced by chicken and turkeys whose moisture content is between 15 and 30% both direct combustion and gasification are potential ways to dispose of the material. Both gasification and combustion effectively reduce the input material to ash, which is a waste product that can be disposed in a landfill or used as a building material, which could be of use to a farm with insufficient spreading area to implement a proper CNMP [28].

Gasification produces synthesis gas comprised primarily of carbon monoxide and hydrogen through a controlled high temperature reaction with small amounts of steam or hydrogen. For a very in depth treatment of the thermodynamics and history of gasification, an excellent reference is presented in [29]. The output of gasification can be used directly as fuel for a turbine or other engine, or as a feedstock for other chemical synthesis operations, such as making methanol or going through the Fischer-Tropsch process to make liquid hydrocarbon fuel [30]. There are several advantages to using gasification to make syngas instead of direct combustion to make steam, including reduced dioxin and sulfur emissions and safer and less volatile bottom ash when compared to direct combustion [31].

There is at least one commercial concern offering a gasification based system that claims to work with dairy manure, Alternative Energy Solutions (AES) [32]. It is unknown at time of writing if any of these systems have been installed or are currently operable.

As animal manure continues to get more wet, it becomes possible to use composting. Composting works best with material with a moisture content of 50% [33]. An excellent definition of composting comes from [34]:

Composting is the biological decomposition and stabilization of organic substrates, under conditions that allow development of thermophilic temperatures as a result of biologically produced heat, to produce a final product that is stable, free of pathogens and plant seeds, and can be beneficially applied to land.

Composting requires that the material be provided with plenty of air, which often times will require the material to by physically mixed, as when stacked in long rows called windrows, or continuously rotated in a drum. The natural heat generation in compost is sufficient to maintain a healthy composting system at between 45-75 degrees Celsius, with warmer temperatures being better for pathogen reduction [35].

Of note in that definition is that the focus of composting is not on producing energy or nutrient management, but on making a stable, pathogen free material for application to land. A healthy composter output looks and smells like good quality garden fertilizer.

Some farms use composting as a way to process solid waste into bedding material for re-use in the barn, possibly in conjunction with a digester [36]. This is the approach taken at Sheland Farms, discussed in chapter 6. Composting, just like direct combustion, uses mostly the solids. The liquid waste stream needs to be treated as well.

There are several vendors of large-scale composting machines, which are essentially a large rotating drum mixer through which air is drawn by a fan. These are often referred to as “In-Vessel Composters”, as they are entirely contained within an enclosure of some type. Manufacturers of these styles of composters include BW Organics, of Silver Springs Texas, L&M Compost Systems, Inc of Holland, Michigan and Green Mountain Technologies of Whitington, Vermont. These machines, like the one used at Sheland Farms, are designed to rapidly and continuously compost materials. Their operation requires far less work than manually turned windrows, but their feedstock needs to be very homogeneous to work effectively. The only energy required for a composting machine comes from the motors required to rotate the drum and feed material. The heat produced by the composting action could possibly be recovered for space heating, although the temperature is not sufficiently high for power generation.

As moisture content increases beyond 70%, the material becomes too wet for use in a composter, and anaerobic digesters become the best practical energy recovery method [37]. Contrary to composting, anaerobic digestion takes place in an oxygen-free environment. A sealed vessel is seeded with material that has a healthy quantity of bacteria, such as wastewater plant treatment effluent, and then manure is slowly added. As long as the volume within the digester stays largely oxygen-free, bacteria convert the organic carbon within the waste into methane, carbon dioxide, and some additional trace gasses. Both liquid and solid waste streams are treatable with anaerobic digestion. The output of a healthy anaerobic digester, known as effluent, has a very low odor intensity and the composition of a highly aqueous homogeneous soil suspension.

Anaerobic environments produce significant amounts of biogas, which contains predominantly methane and carbon dioxide as well as small amounts of hydrogen sulfide and ammonia [38]. Additionally, due to the wet environment of an aerobic digester, the biogas can contain water vapor and trace amounts of other gasses. The hydrogen sulfide can combine with the water vapor, producing sulfuric acid which which can cause corrosion and damage to equipment if not managed properly. Digesters can be very expensive and labor intensive to install initially, but require much less space than windrow-style composting. The technology of anaerobic digesters is comparatively simple compared to direct combustion, due to there being no steam plant associated with digesters. Also, digesters are able to work with a variety of feedstuffs, and work well with very wet materials, as is the case with dairy operations which can utilize a lot of water for cleaning in addition to the aqueous waste streams from livestock.

Certain digester operators charge tipping fees or accept other local wastes into their digesters. The Sheland Farms digester, for example, occasionally serves as a disposal location for large quantities of milk. The Clarkson Pilot plant was at one point used for digesting glycerol. This “anything that can biodegrade” to energy approach makes digesters very appealing for rural settings, as it not only deals with the manure on a farm, but also provides a potential income source if farmers chose to charge tipping fees for others to feed their digester.

Even without tipping fees, adding higher energy feed to a digester can be very beneficial for gas production. Putting nearly any biodegradable material into a healthy digester will increase its gas production when compared with manure, even such standard items as food scraps and grass clippings. For a large table of various materials and their associated biogas potential per kilogram of digested material, see [39].

A significant benefit of anaerobic digesters is that the technology offers the potential to be a reliable, renewable base-load form of power generation. Most other renewable resources, with the exception of hydro and geothermal, are incapable of generating continuously, being dependent on weather for their power production. In the case of an anaerobic digester, however, as long as the digester is kept warm and in good repair, and the farmers continue raising their livestock there will be manure generated which forms the fuel for the digester system. This gives wide-scale adoption of energy from farm waste an advantage when compared to other environmentally beneficial clean energy projects. Additionally, Anaerobic Digestion (AD) generation capacity comes mainly as a side effect of addressing other pressing farm issues, including odor control, bedding re-use, waste material consolidation, and upgrades to waste handling systems for more efficient nutrient use [40].

The EPA believes that anaerobic digesters become economically feasible at herd sizes above 500 head of cattle or 2000 hogs , corresponding with the EPA’s medium to large CAFO regulations[41]. New York State alone contains 15 MW of available generating capacity from anaerobic digesters on dairy farms of 500 head or more using current technologies, constituting 150 total farms [42]. 15 MW of electrical generation, using the average 2007 New York retail electricity rate of 12 cents per kilowatt hour represents almost $16 million worth of electricity every year. Much of this would be in avoided cost to farmers, up to about $106,000 per year per system installed. These estimates are very generous, but even so, farmers able to install anaerobic digesters that can be kept operating for long periods of time will see financial benefits.

Considering that the 15 MW of generation capacity available in New York State consists mostly of generators in the 100 kW range, this amounts to approximately 150 farms capable of dealing with anaerobic digesters. Over the entire United States, the 700 MW worth of potential capacity identified by AgStar would could be as many as 7,000 different sites. To give a measure of comparison, as of 2007 the United States had 616 coal-burning sites providing 33% of the United State’s 986,215 MW total generating capacity [43]. Even in New York, controlling and maintaining the 150 farms currently capable of supporting the equipment is a large engineering challenge.

Farming is a job which traditionally requires very long hours. Farmers are kept busy operating their farms which often requires the maintenance and repair of large equipment whose failure can result in lost revenue for the farm. Although the equipment used on digesters is similar in operation to other modern mechanized farm implements farmers may not have the time or interest in maintaining another piece of mechanized equipment. Evidence from the past indicates the scale of the maintenance problem. During the 1970’s, during the oil embargo, there was much research into anaerobic digesters [44]. As an example of the scope of this research, a literature review of anaerobic digester technologies published in 1979 includes over 100 articles, journal publications, and patents with publication dates from 1977 to 1978 [45].

Much of the equipment installed during this period broke down or failed at least partly due to operator inexperience, lack of technical support, and maintenance issues [46]. Even as late as 1998, the failure rate for continuously mixed digesters approached 70%. Overall, of all 94 digesters either built or in construction in the United States of any kind, 50% have failed since they were originally constructed [47]. Leading causes of these failures were equipment failure or poor maintenance, exacerbated by some farmers who were inattentive to their own equipment. These facts have conspired make digesters appear unreliable and expensive, which has made farmers understandably uneasy about installing them.

However, many of the failures of these early systems could have been prevented with a reliable and robust communications connection to remotely monitor and address situations before they could balloon into major system problems. When in the 1970’s the equipment was first installed, the Internet and computerized, low cost industrial control equipment were not available. With the availability of low cost industrial control hardware and nearly ubiquitous home Internet links, many of these problems can be effectively found and managed, as will be discussed in the coming chapters.

A significant problem associated with running CAFO operations is bedding material. Cows or any animals kept in confined spaces need frequent bedding changes to maintain their health. Many different materials are used for bedding, including sand, hay, shredded paper, manure solids, composted solids, and saw dust. Northern New York has a fair number of large dairy operations that use sand. It is believed by many that sand provides the best material for bedding dairy cattle. The relative merits of sand and other bedding systems are beyond the scope of this thesis, but the Cornell Waste Management Institute at Cornell University’s Department of Crop and Soil Sciences has a very complete and thorough literature review available online which summarizes the results of more than fifty papers in this area [48].

Using sand presents unique operational difficulties for running anaerobic digesters. The original impetus for the Clarkson Biomass Group was to study digester operations using sand bedded dairy cows. Sand bedding needs to be either efficiently removed from a digester or removed from the manure stream before going into the digester to prevent the digester from silting up with indigestible solids over time. In order to do this a pilot scale plant was needed which could be easily installed and re-configured for various sand separation technologies.

The evolution of the digester continues at Clarkson, and a focus has now shifted to laboratory scale experiments and verifications based on the sand-separation experiments performed using the previous pilot plants. While the focus of the research project is sand removal technologies, there is also considerable work going forward in the area anaerobic digester control and efficient design. The following sections present the systems as installed on the pilot plants so the reader can become familiar with the particular concerns of digester operation driving the coming control and power discussions.

None of the Clarkson digesters were fit with generators and their associated line-voltage AC interconnection equipment, due to their small size. There are many off-the-shelf standard control and remote telemetry solutions for generators which are available from the generator manufactures themselves. Therefore the focus is on the digester itself with the assumption being made that if reliable failure analysis can be provided to illustrate the effectiveness of remote sensing and real-time data on digester operation, then an already available generator control system can be integrated with the digester control solution.

A generalized diagram of a digester is shown in Figure 2.1 which shows standard blocks common to all farm-size anaerobic digesters. All digesters require some sort of storage vessel, which needs to be sealed from the outside environment to prevent air from entering and biogas from leaving. Some vessels have built in gas storage facilities whereas others may require external gas storage in order to maintain pressure in the tank.

All digesters require some sort of heating system to maintain the temperature of the contents of the vessel near optimal for that design. Some large anaerobic lagoons may not have active heating, but still feature some form of insulation or thermal monitoring to judge digester health. More advanced systems will have multiple heat sources, possibly including in-tank or external heat exchangers supplied by engine heat or an external water heater.

Additionally, there is always some form of manure handling system. For the purposes of this research, the manure handling system is that which is used on the digester itself, including feed pumps and tank mixing systems. Whatever the farmer uses to get the manure to the point where the feed pump is responsible for it lies outside the scope of the digester.

All digesters have some kind of biogas handling system. The primary goal of this is to deal with the gas in a way optimal to the farmer’s operation. Gas handling may include any monitoring, storage, or treatment for the gas. The gas handling system is the equipment used in between the digester tank and the equipment which utilizes it. Gas use equipment could be, for example, be a prime mover for a generator, domestic home heating system, or even flaring to the environment.

A control system holds all the systems together and provides for remote monitoring and control. Ideally, a scalable digester controller will implement necessary functions to control the equipment contained in Fig 2.1. The controller developed later will allow for standard control on the basis of this block-diagram digester for a high level view of the requirements of scalable digester control.

The initial Clarkson digester was designed by Mtarri / Varani LLC of Golden, Colorado to test the operation of a means to remove settled bedding sand from within the digester tank after undergoing bio-degradation. It was thought that the sand could be made clean and removed from within a digester tank, and that raw sand-laden manure could be supplied to the digester and the solids efficiently removed. This system was operated from September 2007 through mid-December 2007 when it had to be turned off due to weather. The operation of this system was essential for design decisions which resulted in the scalable control system employed on the Version 2 digester. For readability, the diagram has been omitted from the main body, but is available in Section 11.5 [49].

The Mtarri / Varani design came with no electrical system, and a rudimentary controller and thermostat system for tank temperature control was implemented rapidly by the author before deployment, which featured limited automatic control features. Feeding and mixing were performed by operating switches on the front panel. The construction and operation of the this system, requiring frequent visits by Clarkson students to perform maintenance and take samples, clearly demonstrated the requirement for an automatic local control system. Originally, a great deal of control and monitoring hardware was purchased for this digester, but most was not installed due to considerable operational difficulties and time pressure. However, virtually all of this hardware was eventually used on the Version 2 digester.

The PLC on the Mtarri / Varani digester was used as a datalogger only, and monitored temperatures and gas properties. The measured channels included heater system temperature, tank temperatures, ambient temperature, gas flow, and methane concentration. The logged channels are summarized in Table 2.1.

|

The initial Clarkson Digester provided valuable insight into what features were required and which were not. These lessons were taken under advisement and the parts of the old digester were transformed into a new one over the winter. The initial digester was designed to test the feasibility of in-tank sand separation. It was decided that the new digester should only be for digesting, and that the sand separation would be performed outside the digester vessel itself. It was therefore decided to re-construct the Mtarri / Varani design into a new digester, whose sole purpose would be a digester and a source for reliable effluent for use in sand separation experiments. The new digester would also feature a state-of-the art control system, designed to meet the needs of the experimenters while also providing sufficient data for troubleshooting and feasibility studies related to remote operation.

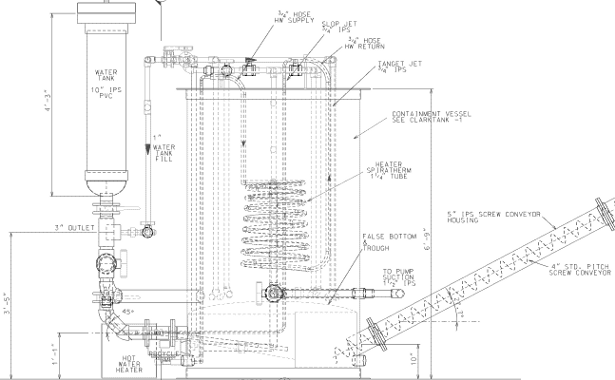

Using the lessons from the Mtarri / Varani digester, a new system was designed and constructed. Most of the new digester was a rework from the original digester, with new plumbing and manure handling systems. The control system was totally redesigned for the new digester, and all of the purchased control hardware was installed on this new version. A diagrammatic view of the new version is shown in Figure 2.2. Additionally, a side view of the digester is shown in Figure 2.3. What follows is a short discussion of each of the key systems, as follows:

This section is meant as a brief overview to familiarize the reader with the components of the digester. Much more in-depth discussion of the control system follows in subsequent chapters. In the Mtarri / Varani digester, the controller was merely used to log data channels. In the new one, the installed controller was responsible for the following operations:

As a result of the group’s experiences with the Mtarri / Varani design, it was decided that as much should be automated as possible to prevent frequent site visits. The system still needed to be fed by hand, due to the requirements of the sand separation experiments, but the system was implemented in such a way as to make this as repeatable and as easy as possible for the operators. The features included in this include a gravity-fed graduated feed hopper, automatic pump operation during feeding, and programmed regular mixing intervals without operator involvement.

Eventually, the controller was to operate in fully-automatic mode, performing its own feeding and system maintenance tasks, but this once again was delayed due to the need to get the digester back in the field for summer testing. Table 2.2 shows the telemetry channels logged for version 2. There was also an ultrasonic flow meter installed on the tank return line, which was not logged automatically by the control system due to the intermittancy of the pump operation and the very long response time of the flow meter. These values were recorded manually when the tank was fed by the operators of the system.

|

This control system worked well, giving carefree operation over the course of the whole summer. One month before the conclusion of the summer’s work, a power logger was added external to the digester itself. This was originally designed to be installed as part of the control system, but due to time constraints was not initially integrated. Post-processing of the power data from this logger is explained further in Chapter 4.

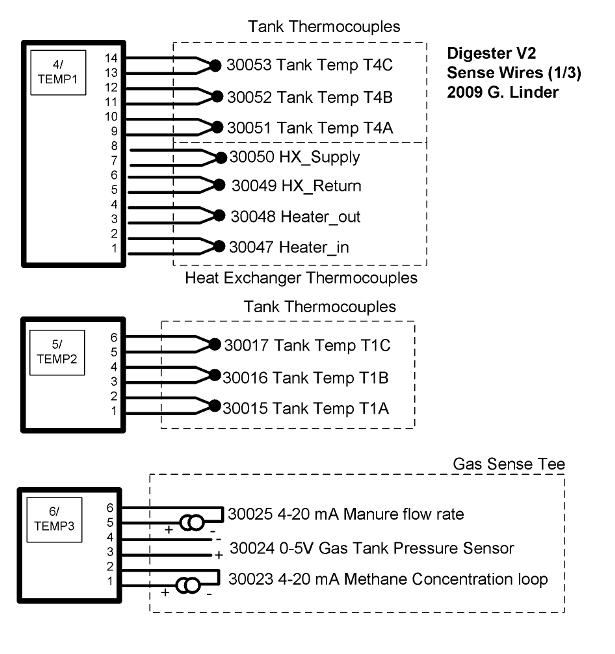

For the Initially there was significant interest in monitoring tank temperature, so the digester tank was instrumented with 12 thermocouples at varying heights and distances into the tank volume. The data from these thermocouples was to be used for comparison to a fluid dynamic model. This model has not yet been completed, and although the data was briefly analyzed by the author, it is not immediately relevant to this thesis.

Due to several thermocouples being damaged and lid access issues relating to plumbing and wiring, the new digester featured a different thermocouple layout, using fewer thermocouples in different positions than in the Mtarri / Varani design. The thermocouple positions within the tank of the version 2 digester are shown schematically in Fig. 2.4. The “abc” in the figure refers to inner to outer (a = innermost thermocouple, c= outermost). In addition to these 12 thermocouple channels, there were 4 thermocouples in the water heater system, 2 in the manure heater system, one in the manure pump, one in the gas tee, and an ambient temperature sensor, for a total of 21 temperature channels.

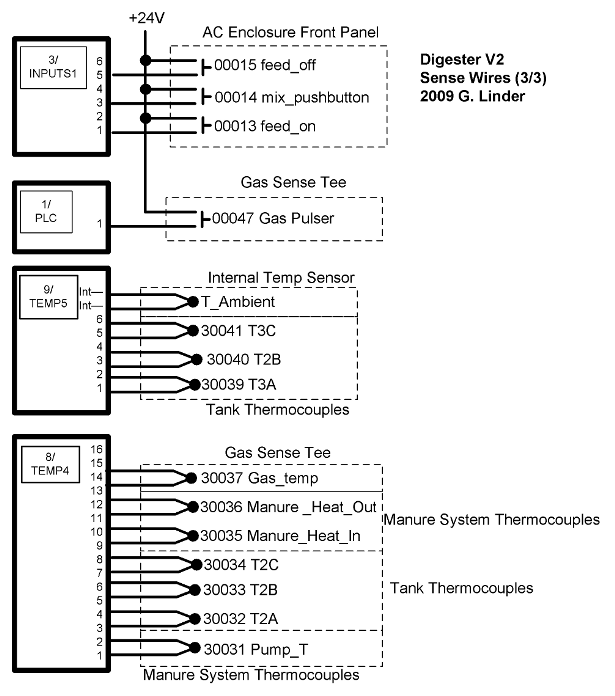

The control system was implemented primarily from parts from SixNET, a manufacturer of open-source PLC (Programmable Logic Controller) equipment and peripherals. In addition to this, standard off-the-shelf circuit breakers and contactors were installed according to National Electric Code (NEC) sizing specifications in the “AC Enclosure”, which enclosed all the line-level AC equipment. The types and quantities of non-AC related devices used in the combined controller/DAQ are shown in Table 2.3. The enclosures were all National Electrical Manufacturers Association (NEMA) 4X rated weatherproof enclosures, and all conduit and cabling was installing according to standard practice for outdoor electrical equipment.

|

The SixNET hardware was chosen primarily because of its low cost and out-of-the-box data logger functionality. Other PLC vendors were examined, but the SixNET hardware seemed to have the most features for the least amount of money. In addition, they are based in Clifton Park, New York and have very friendly and helpful staff.

Physically, the controller occupies four weatherproof enclosures, two on the back of the unit and two on the side. These enclosures are labeled “DAQ”, “HMI”, “AC”, and “PLC/DAQ” in Fig. 2.2. The internals of the two main enclosures are shown in Fig. 2.5. At left is the AC enclosure, with circuit breakers along the top row and contactors along the center. At right is the main PLC enclosure. There are two modules mounted remotely in the DAQ enclosure to save thermocouple wiring. The HMI is mounted on the side of the tank to be at appropriate eye level for system operators.

The digester tank is an integral part of any digester system. The initial version of the Mtarri / Varani is shown in Fig. 2.6[50]. Notice the false bottom and trough features. These systems were removed when the tank was refit for the version 2 Clarkson digester.

|

|

The digester tank has a height of 6’9” and a diameter of 4 feet, making its total volume approximately 634 gallons. Elsewhere, the tank is referred to as having a volume of 515 gallons. The difference is because of the need for head space in the digester tank, and the need to account of the plumbing system totals in the manure tank volume. The plumbing uses around 45 gallons to fill the pumps and 3 inch manure system.

A small volume of the digester is lost because of the internal heat exchange and related tubing in the Clarkson digester, but this amounts to less than three gallons, which is the total volume of the fluid in the heating system. Therefore the “hydraulic volume” of the Clarkson pilot digesters is 515 gallons. The head space of the digester therefore represents a volume of 164 gallons, or 22 cubic feet. Under normal operating conditions, the liquid level in the tank is then 1.75 feet down from the top.

In Fig. 2.6, this corresponds to the level of just beneath the second 3/4 inch sampling port. The actual tank delivered had an additional penetration not shown in this figure, directly opposite the line of sampling ports which was used for the effluent weir.

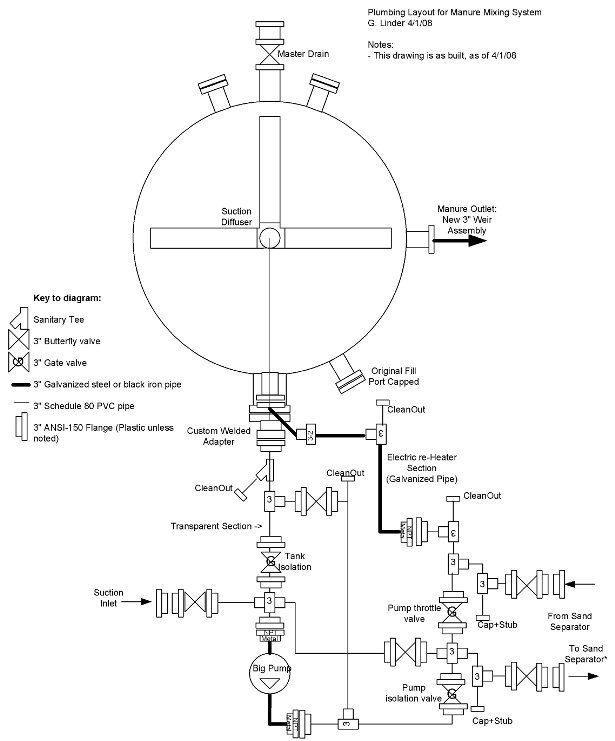

The feeding, mixing, and effluent output are all collectively known as the manure handling system. This includes the 3 inch diameter plumbing, large pump, valves, and other equipment used to mix the tank. For clarity, the diagram of this system has been omitted from the main body of the text. The manure plumbing system as deployed on the pilot plant is illustrated in Section 11.2.

Before describing the manure handling system, a brief discussion of the properties of sand laden dairy manure is worth presenting. For those who have not experienced sand laden manure, its consistency is similar to that of watery oatmeal, if one were to add a good cup of sand and a handful of grass clippings to a standard breakfast portion. The material is easier to move with a shovel than a pump if not watered down a bit. The more watery the material, the easier it is to pump. However, with sand in the manure stream, the more watery the material the more rapidly the sand tends to fall out. Currently, there is ongoing research at Clarkson to precisely characterize the physical characteristics of sand / manure slurry, but the net effect is that it makes a very demanding material to send through pipes. Additionally, manure used in this project comes from the floor of a good size dairy operation. This means that other materials get into the manure as well, including such pump-unfriendly objects as gloves, corn husks, tools, and other non-pumpable items. This combination requires vastly oversized plumbing from what seems appropriate to mix a digester with a hydraulic volume of 515 gallons.

The initial Clarkson digester was equipped with a prototype sand removal system which featured small scale pipes intended to pump the liquid fraction of the digestate in order to facilitate in-tank mixing without the aid of a large pump. This system turned out to be highly unreliable in practice, due primarily to the use of small diameter pipes in the plumbing system. It was decided, when the system was re-built, to have nothing smaller than three inch trade size through which manure or effluent was expected to flow. Some compromises had to be made to this, due to the requirement to re-use the tank from the initial digester. This resulted in having a single two inch and a single inch-and-a-half feed throughs on the tank itself. Additionally, the new plumbing system was equipped with threaded clean out ports adjacent to every bend and elbow in the system. When moving solids suspended in liquids, the solids tend to settle at flow disturbances, such as corners and valve seats. Every effort was made to make these locations accessible via cleanout plugs, to avoid having to dismantle pipes to get at blockages, as was the case with the previous digester. The plumbing diagram in Section 11.2 shows the large number of cleanouts in the system.

Part of the manure system is wrapped in heater tape. This length of pipe, which also holds the transducers for the manure flow meter, was intended to be used to compensate for the cold injection of manure which occurred each time the pump was started. The self-regulating heater tape was left running continuously.

The pump itself is a 5 HP Gordon-Rupp chopper pump with three inch trade size ports. Initially, this was purchased and field-installed on the original digester. In normal operation, the tank contents are sucked from the bottom of the tank, through a cross of pipes designed to avoid blockage, circulating through the piping and throttle valves, and returned at the top. The intent of this was to provide for turbulent flow at the top of the tank to continually break up the scum layer. As such, the “return” line is placed just below the “full” level mark on the tank.

In the Mtarri / Varani design, settled solids were found to be a significant problem, even with a gas blower system installed. The original intent of this gas blower was to recirculate the biogas from the top of the tank into diffusers mounted in the center. This should have agitated the manure enough to settle the sand into a trough in the center of the tank, while at the same time providing the required agitation of the tank. This system did not work, due to the diffusers themselves eventually being buried beneath settled solids due to the failure of the sand removal system under test.

In order to facilitate tank mixing and re-suspension of solids in Version 2, a manual pump reverser was installed, illustrated in the appendix in Section 11.2. This is a set of valves which reverses the inlet and outlet of the pump, allowing the mixing pump to suck from the top of the tank and return through the bottom. This was installed to allow the full force of the pump to agitate any settled solids which settled on the bottom of the tank. A side effect of the pump reverser system was that it provided an effective and reliable bypass pump throttle to allow controllable mixing rates from the fixed speed pump.

The pump reverser was tested, although it was found that the solids settling in the tank were not a significant problem over the operating period of the second Clarkson digester. This was largely due to the use of an external sand separator resulting in very little solids being introduced into the tank in the first place. The mass balance results of the sand separator trials are shown in Fig. 2.7, which clearly illustrates that the vast majority of sand is removed before the slurry is pumped into the digester tank [51]. The first version digester, designed by Mtarri / Varani LLC utilized this same feedstock directly and put 100% of the solids into the digester which contributed to the need for a pump reverser system.

The manure system includes a feed hopper. In operation, the material to be fed to the digester was dumped into the feed hopper. Then, a “start feeding” push button was pressed on the control panel. This turned on the PLC’s feeding program, which performs mixing and electrical load control for the system. Once the pump was running, operators would operate two valves on the pump inlet side which forced the pump to suck from the feed hopper. Once feeding was complete, the feed valves were reset to their operating position, and the “stop feeding” button was pressed on the control panel, telling the PLC that feeding was complete and it could return to standard mixing and heating operations. The digester was normally fed approximately 20 gallons per day in two feedings, one in the morning and one at night. The feeding volume and times changed throughout the summer in response to data from the digester.

As the feeding was taking place, the effluent would be discharged through a three

inch transparent weir, sometimes also called an outlet box or goose neck. The height of

this device was set to maintain the appropriate pressure inside the tank which

was 8 inches of water (0.3 pounds per square inch). Adding material to the

tank caused an equal volume to be discharged through the goose neck. This

gravity discharge system worked well, with the lone exception of being one of

the remaining small-size fittings on the tank, requiring cleaning during the

summer.

inches of water (0.3 pounds per square inch). Adding material to the

tank caused an equal volume to be discharged through the goose neck. This

gravity discharge system worked well, with the lone exception of being one of

the remaining small-size fittings on the tank, requiring cleaning during the

summer.

Due to the fluid properties of manure, automatic feeding as low as 20 gallons through three inch pipe is very difficult to automatically meter effectively. Automatic feeding was further hampered due to the fact that the sand separation experiments required the mass of each volumetric feeding to be known precisely. Manure is highly non-homogeneous, and in order to get the reliable data for the system’s mass balance, each feeding had to be measured individually. Using buckets and scales, operators were able to measure volumes accurate to less than half a gallon and weights to less than 1 pound. Each feeding consisted of a filling gallon buckets from the raw slurry. These buckets were then weighed before being poured into the feed hopper, which was marked at the appropriate volume for that particular days feeding. Performing this task under automatic control would have required some mechanism able to measure both the mass and volume of a manure flow, while also being easy to interface with the system’s manure supply, which consisted of 250 gallon plastic tanks used to transport manure from as far as 70 miles.

Additionally, the experiments on which the digester was used required intermediate mixing and buffering stages to prepare various ratios of effluent, water, and manure for sand separator characterization. The equipment required to fully automate a sand-manure separator plant and digester are easily implemented on large scales with large flows and pumps where volume can overcome the manure handling issues and precise measurements of mass flow are not required.

The biogas handling system consists of the equipment required to safely remove the generated gas from the digester as it is formed. In a full scale system, the output from this system would feed into a prime mover or water heater through some kind of scrubber system. Due to the small scale of our system, the gas was flared or merely vented, depending on the flow rate of the gas. The small volume of gas produced by the Clarkson plant is not sufficient to even maintain a small flame on a Bunsen burner. Therefore, it was decided that not flaring the gas and merely venting did not pose a safety concern. However, on very large scale digester, producing 100’s of CFM of biogas, an improperly operating flare poses a potential safety risk.

The digester gas system consists of a gas pipe leading from the top of the tank to the gas sense tee, through the volume meter, and then down a pipe to a combination back pressure regulator and water trap. The output from this then went to a flare, whose design was modified extensively by the manufacturer to accommodate our low flow situation.

The first several feet of pipe, and the all the gas instrumentation itself, was wrapped in heat tracing to prevent the biogas from condensing inside the instruments. The heater tracing should have been able to keep the heater tracing at a temperature far about the 37 C of the digester tank, although this was found to be difficult. Data indicates that the heater tracing gradually cooled off over time, despite the fact that energy was applied, and the tape was warm to the touch. The insulation over the heater tape was exposed to the environment, and any water which may have got between the gas piping and the insulation would greatly effect the heater tape’s ability to maintain the gas temperature. In addition, the top 3 inches of the tank itself were not insulated at all, to provide access to the bolts used to attach the lid. This happens to correspond to nearly 1/4 of the exposed gas area at the top of the tank. Therefore it seems plausible that the gas was in fact much cooler than the digester tank liquid, perhaps even enough to condense inside the gas piping directly over the top of the tank. This would have created a substantial additional heat demand which was beyond the capacity of the heater trace to provide.

These experiences have led to the understanding that a system based on cooling the gas may be a highly efficient and reliable way to remove damaging hydrogen sulfide from the digester gas stream. In winter, a sufficient temperature difference exists between the gas space in the digester and the outdoor temperature to condense most of the water out of the gas, which would take the water soluble hydrogen sulfide out as well. This may require a blower to increase the energy of the gas sufficiently to supply the engine of the generator set but is simpler and lower maintenance than other potential gas cleaning technologies.

The gas sense tee contained the tank pressure sensor, gas temperature thermocouple, and optical methane concentration sensor. The methane sensor in particular is very sensitive to both moisture and hydrogen sulfide, which is why keeping the gas from condensing was very important. The tee was plugged immediately into a standard bellows-type volumetric flow meter rated for natural gas service. This is the type of meter which is a standard piece of equipment on most houses with piped natural gas supplies. The meter is not designed for biogas service, due to hydrogen sulfide reacting with parts inside the meter, but it was decided that the meter, due to its low cost and very low pressure operation, was ideal for the length of operation planned. A full scale system would need to user a proper style of gas flow meter, or sufficiently clean and dry the gas to make a bellows-meter reliable. As part of this decision, the low flow of the gas system needed to be considered. Whereas a full scale digester could accurately measure flow using a turbine meter or other type, our low flow rates basically required a bellows-type meter, which accurately measure even the smallest of gas flow rates.

After the gas characterization equipment, the back pressure regulator was next. If a

generator was in place, this device would not be required, as some other gas pressure

regulator would maintain the tank pressure at its design point. Merely venting

the tank directly to the flare is not a valid idea, as sufficient positive pressure

must be maintained within the tank to maintain an anaerobic environment. In

the Clarkson system this pressure was 8 inches of water or 0.3 PSI (pounds

per square inch). Trials showed that six inches of water in the back pressure

regulator was sufficient to maintain the tank pressure at this design pressure.

The other two inches of water were taken up by pipe losses and the meter

itself.

inches of water or 0.3 PSI (pounds

per square inch). Trials showed that six inches of water in the back pressure

regulator was sufficient to maintain the tank pressure at this design pressure.

The other two inches of water were taken up by pipe losses and the meter

itself.

After the back pressure regulator, the gas was flared in a commercially available biogas flare, using a spark igniter. It was found that the gas flow was insufficient to support continual combustion. As such, flames were visible only during mixing and feeding operations, when the gas flow increased. Wind was otherwise sufficient to extinguish the flame, despite the flare’s wind covers.

The tank heater system consists of equipment and plumbing required to control the digester tanks temperature within appropriate bounds for the experiments being conducted. The heater system is capable of operation up to 50 C, although it was set to operate at 37 C for the duration of the summer’s experiments.

In the Mtarri / Varani digester, the heater system used a standard under-sink hot water tank and a very undersized pump. This pump was replaced with a generously oversized pump from a different project which was valved down to maintain the flow. The heat exchanger consisted of a stainless steel helical coil suspended from the lid. This configuration meant that a crane or hoist was required to remove the tank lid. Long rubber hoses were connected to this coil via tank top penetrations through a large number of various metal-to-plastic-to-metal threaded fittings. The fittings on the tank top were a continual source of frustration, as the rapid temperature cycling intrinsic in on-off heater control provoked these fittings develop leaks. The experiences with this system lead to lively debate and a vastly improved water heater system in version 2.

The version 2 Clarkson digester featured a stainless-steel flow through heater element and all soldered copper piping outside the tank. The heater fluid went through existing penetrations in the tank wall to flexible pipe segments feeding the existing helical coil. The helical coil was attached to stainless steel brackets welded to the inside of the tank. This not only allowed the tank lid to be managed by three people, but also meant that the tank, when open, could be easily entered and exited by standing on the coil support brackets. A properly sized heater pump was purchased based on pressure drop calculations and verified by measurements on the actual heater system.

The system is filled with a 50/50 glycol/water solution similar to that used in car engine coolant loops. The system was not drained for the winter upon completion of experiments. A recent inspection of the heater system after a typically rough and cold North Country New York winter showed that the heater loop has not leaked, and the system pressure is still at 3 PSI as it was when the system was taken out of service six months earlier.

The digester needed to be transportable, and as such was designed from day one to be carried on a trailer capable of being towed by a standard pickup truck. This required that the systems be not only reliable and robust from the point of view of weather and farm service, but also stable enough to be transported at highway speeds with a minimum of maintenance.

Additionally, it was found during the deployment of the original digester that access to the top of the tank and support systems was very important. The Version 2 digester features a support structure surrounding the tank that was designed to hold not just the plumbing and electrical enclosures, but also the weight of operators and equipment required for maintenance. A ladder was constructed to allow easy access to the top, and framing was constructed all the way around the tank to allow operators to reach valves and instruments without needing additional ladders or lifts. This system is illustrated graphically in Fig. 2.2.

Equipment access is of significant importance to digester maintenance. Due to the size of even the Clarkson digester’s modest 515 gallon tank, easily reaching the various thermocouple penetrations, valves, and gas systems is very important for system reliability. Human access to digester systems should be taken into consideration whenever possible, so as to avoid injury and time wasting disassembly and reassembly procedures.

The author assisted with the initial deployment of the first Clarkson anaerobic digester and participated in its operation and helped address various pumping and maintenance problems. The knowledge gained through this experience was applied to the construction of the second digester. The version 2 digester was designed predominantly by the author with the valuable assistance of Dan Valyou, Shaun Jones, and the Clarkson Biomass Group. The basic trailer and components of the original Mtarri / Varani design were re-used and the system was designed and constructed over a period of 12 weeks from December through February 2007-2008 with the dedicated assistance of members of the Clarkson Biomass Group and the support of the Clarkson machine shop.

The author analyzed shortcomings in the Mtarri / Varani digester, including deficiencies in the heating system, gas system, control system, and plumbing system and implemented solutions in the new version. Lessons learned in the engineering work that went into this design are described in more depth in Chapter 11.1. The Clarkson digester version two includes a state of the art local controller that is capable of being affordably upgraded to support real-time remote control capability, as described in Chapter 7.

Having a familiarity with the components of digesters from Chapter 2, this chapter will fill in the knowledge with an in-depth discussion of the local control system used on the Clarkson anaerobic digester. Having done that, an in-depth discussion of farm electrical loads and the impact of full-scale digester electrical systems on farm electrical service will be presented. These issues are all important to understand before an effective strategy of remote control can be developed in the coming chapters.

The time line of the development of this controller started as being a local controller for a system with a built-in bottom-mount sand removal system. This was the Version 1 digester, described earlier. Due to effort required to get the pilot plant mechanics operating, the controller wasn’t prepared in time for the initial installation on site, and all control functions were done by hand via front panel switches operating the AC contactors. During the trial period of the version one digester, the local controller was re-designed and further hardware ordered to meet the requirements of what was expected to be the version 2 digester. More thermocouples, more motors to operate on the various proposed sand separators, and more data channels. The ultimate goal of the Version 2 digester controller was to monitor nearly 40 temperatures around the tank as well as operate some kind of external sand separation equipment. This equipment was never constructed, and the equipment used in its place had its own on-board controller.

All the extra Input-Output (IO) equipment purchased for these goals was left unconnected. There are still contactors inside the AC enclosure with manual control switches labeled for use with a proposed sand separator design. After all of this, the goal was to deploy a web-interface for the digester enabling real-time control. This was not complete by the time the digester went on-line for the summer, although work has been moving in that direction. Discussions have been under way between the author and professors in the biomass group to complete the installation of a cellular data link over the summer based on the findings of this thesis.

The addition of a more expensive firmware license to the current digester hardware will enable the digester to interface with on-line monitoring options available from various vendors, discussed in Chapter 7. Any vendor who offers a system which is capable of dealing with a Distributed Network Protocol Version 3.0 (DNP3) data stream, including those companies presented in section 11.8 are potential remote monitoring candidates. Future work to improve this controller will require a candidate familiar with various industrial control technologies, including DNP3 and the International Electrotechnical Commission (IEC) 61131-3 PLC programming specifications. In addition, knowledge of standard electric wiring practice and the Open Systems Interconnection (OSI) model for computer networks would be beneficial.

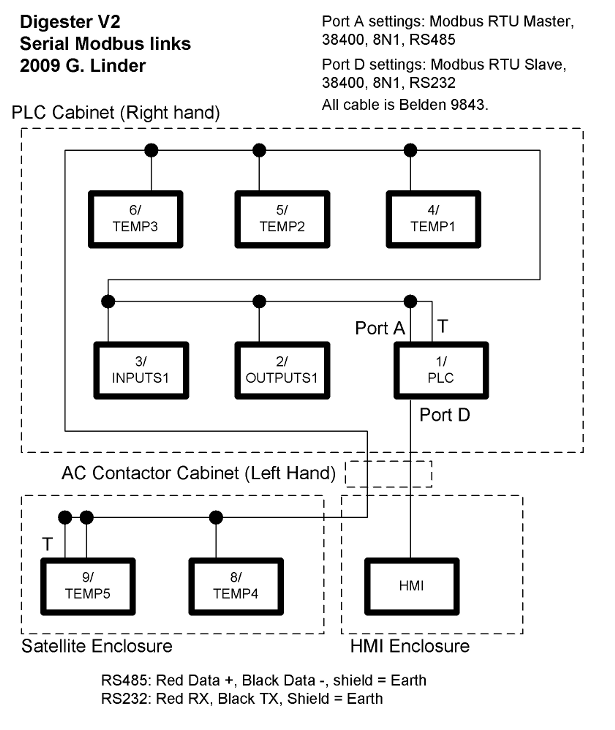

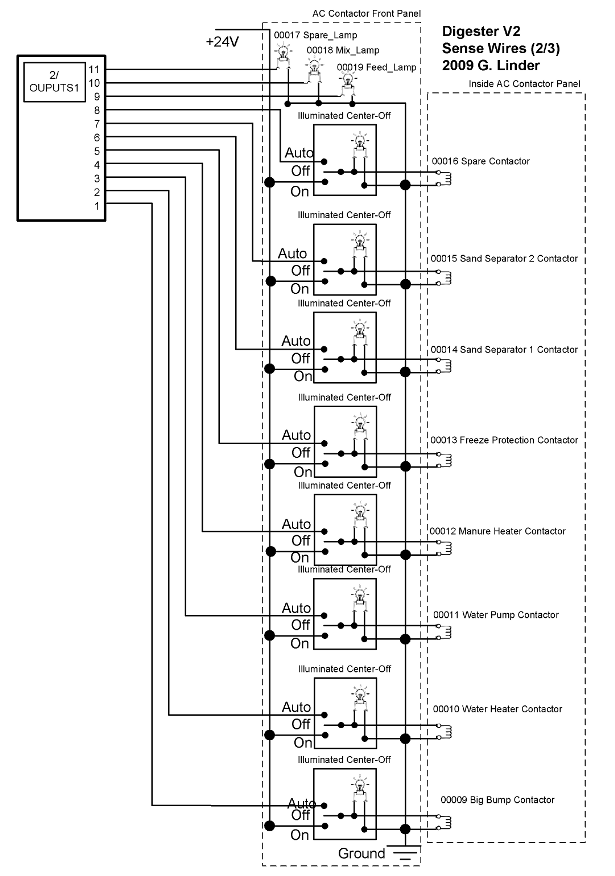

The digester’s control and DAQ system consists of a Programmable Logic Controller (PLC) and seven standard Input-Output (IO) modules connected locally over a daisy-chain RS-485 link. A daisy chain link is a standard wiring method in industrial systems, whereby the devices are plugged one into the next, often times with the wires coming from a device and going to the next device merely wrapped together and attached to the center device. This is illustrated graphically in Fig 3.1, which shows the RS-485 line going in a single path from the PLC through OUTPUTS1 and into INPUTS1. All the wiring for this signal is twisted-pair jacketed high quality cable. An LCD control panel is attached via a separate RS-232 connection to the PLC. All inter-device communications use the Modbus protocol.

Modbus was originally a trade name for the communications system developed by the inventor of the PLC, Modicon, in the late 1970’s. Since then it has become an open and freely available defacto communications standard, which is nearly ubiquitous on low-data rate sensing and control equipment. Modbus can be carried over a variety of electrical connections, including modern Ethernet TCP/IP connections. An excellent overview of the Modbus protocol is provided in [52].

In general, Modbus provides for coils, contacts, and analogs. A coil is analogous to a relay, and can be turned on and off. A contact is analogous to the contacts in a relay, and are turned on and off by other coils, or by external inputs. Analogs can be either read or written, and support various fixed point data forms depending on the type of analog value to be dealt with. A single Modbus system can have up to 256 devices, each device capable of having 9998 each of coils, contacts, analog ins, and analog outs. The digester channel list in section 11.6 shows all the Modbus addresses and channels. The SixNET column is used for mapping of Modbus channels to SixNET’s addressing system.

The main manure pump, for example, can be turned on by telling the Modbus representation of the coil with number 00009 at address #2 to energize, which in the hardware turns on a transistor which drives the contactor located in the AC cabinet, energizing the pump. A contact can be read, as is the case of the front panel switches, by reading the state of a virtual relay contact. Closing a front panel contact energizes a virtual Modbus coil which closes a virtual Modbus contact which is read by the software to tell the control program that the front panel switch has been closed.

Modbus was originally designed as a replacement for early automation systems. These early systems consisted of large boxes full of electromechanical relays and timers wired up to implement logic functions. Modbus was developed to enable people familiar with wiring large cascades of relays to easily replace those boxes of relays with easily reconfigurable controllers without substantial personnel re-training. The Modbus protocol when compared to modern industrial protocols like DNP3 seems very archaic because of these origins. However, because it relates obviously to physical relays, coils and other common industrial equipment it is a very popular and widely supported standard.

A Modbus compliant device enables reading and writing of coils, contacts, and analogs in a master-slave arrangement. The PLC forms the master of the digester controller, and all the other devices are slaves, forming “virtual IO” to the master station. This means that all the Input-Output (IO) modules in the digester, labeled in Fig. 3.1, are seen by the PLC as local input and output devices. The PLC, labeled as Address 1, when accessed via the Ethernet port looks like it has all the other channels of the other seven devices locally available. The goal of this topology originally was to make remote interfacing easier.

The PLC contains additional support for remote access over a different set of protocols, whereby having it appear as one large PLC with multiple inputs and outputs as opposed to multiple devices with their own inputs and outputs would be useful. The goal of the system was to be as integrated and simple to interface with as possible to the outside world. Describing this makes it seem more complex than it really is. In actual practice, the development of this kind of input-output system is easily handled in software packages available from the PLC’s manufacturers, literally as drag-and-drop or spreadsheet type interfaces. In the case of the Clarkson Digester, the software used to do the IO setup was the SixNET toolkit, available from the PLC’s manufacturer.

The actual amount of control and DAQ hardware installed on the pilot plant is in excess of what would ordinarily be required. The system has 40 analog instrumentation channels, 6 analog voltage input channels, 24 digital outputs, and 24 digital inputs. As presently implemented, less than half of all channels are actively utilized. This over design was due to changing design goals as the system progressed, while needing to be able to potentially control and monitor a sand separation and cleaning system. Additionally, the tank was originally specified to have three times as many thermocouples as were ultimately installed. The result of this is that the pilot plant has a controller capable of operating a very large digester, or an entirely integrated farm waste management system complete with remote web-based management.

What follows is a discussion of each of the four blocks presented in Fig. 2.1 and what particular equipment and algorithms were implemented in their control. The four blocks are heater system, manure system, gas handling, and control. For purposes of this section, the control part of this view will cover issues relating to power monitoring, as the control system would need to be responsible for controlling not just the digester, but also the “gas use equipment”, which may have its own electrical interface. Each section discusses the system and its local control loop, and which variables of that loop would be essential for remote monitoring in order to effectively diagnose problems.

Pursuant to the goals of applying modern SCADA protocols to anaerobic digester control, the author implemented all control features in one of the languages defined by IEC 61131-3, known as Functional Block Diagrams (FBD). Due to the need present them full-size for readability, the FBD diagrams for the four key control aspects of the digester are presented in Section 11.7. In the sections which follow, these FBD diagrams are referred to when referencing the sections they control. The information contained in sections 11.6 and 11.7 constitute the majority of the details associated with the firmware of the digester. The program used to program the PLC was ISAGRAF Version 3.47, provided by SixNET for use with their hardware.

The heater element is a 240V flow-through unit rated at 4 kW. The control system consists of two different loops, one for maintaining the water temperature and one for maintaining the digester temperature. With electric flow through heaters, care needs to be taken to not over heat the water if the water is not flowing. For this system, the heater unit will not operate without the water pump being energized first, and if the water pump is de-energized, the heater shuts off. Control commands for the heater are generated by tank temperature averaging. All nine thermocouples submerged in the digester tank are averaged together, and that result is used to to determine the tank temperature.

The LCD interface contains a heater set point display, which allows for the user to set the maximum water temperature and the tank temperature. In operation, the flow-through heater element raised the water flowing through it an average of one degree Celsius. Trials were performed with the water not flowing and the heater on, and the 4 kW unit was capable of boiling the water in less then 2 minutes if the pump were to shut off. In a full size unit, the heater system may be of an entirely different design, perhaps piping the contents of the tank itself through an external heat exchange, instead of an in-tank spiral heat exchanger as used here. However, the basic system required to observe operation of the tank temperature control system are the same. The control system is illustrated in Figure 3.2, illustrates the two separate but coupled heater system control loops.

As currently implemented, there are four thermocouples in the heater loop itself, plus the “virtual” average-temperature reading thermocouple installed in the tank. Additionally, there is a turbine flow meter in the loop as well as two pressure indicators, on the suction and discharge of the heater system pump. An ideal design would include all of these devices automatically logged and recorded, however this is not necessary in order to establish if the system is operating correctly or not. The control loop in Figure 3.2 uses only the tank temperature and heater element outlet as its input variables. It therefore follows that these two data points are sufficient to tell of the heater loop is operating per specification. As will be presented in Chapter 5, a digester whose heater fails can be diagnosed by paying attention to various temperature variations, and complete monitoring of the multiple thermocouples as performed for this installation is not strictly necessary in a real world digester.

The heater system FBDs, presented in section 11.7 are HEATCON (section 11.7.2) and CALCTEMP (section 11.7.3).

The manure system plumbing is illustrated in Chapter 11Section 11.2. The manure system consists of one automatically controlled component, the five horsepower manure pump, and several manually operated valves. In the case of a full scale digester, these valves would be automated, or else separate pumps would be used, one for mixing, and one for feeding. The operation described here includes the processes which need to be manually performed, under the assumption they could be made automatic with only additional equipment. The controller design took this into consideration, and features extra open input and output terminals and AC contactors and relays for operating valves. Additionally, there are “hooks” in the control code to allow for easy automation of the valve commands.

The manure handling system is chiefly responsible for two key tasks on any digester. These are mixing the tank and feeding the tank. In some digesters, the mixing takes place as the system is fed, while in others, such as ours, they are distinct actions. It is important to the operation of a digester that the temperature be kept as uniform as possible within the tank. This is the goal of the tank mixing system. Some digesters, notably plug flow systems and lagoons, are unmixed, and therefore have simpler control needs than continuously-mixed type tanks. However, continuously mixed type tanks can be smaller and have shorter residence times, as well as increased gas production, due to the increased bacterial action that comes from mixing.

A significant limiting factor placed upon our digester was the available electrical service. More on this topic in Chapter 4. Our target farm had available only a single 30 Amp split-phase outlet with no neutral for powering our digester. This meant that we had 240 V AC available for use. A 5 HP pump, rated for 240V split phase service, requires about 23.5 amps full load, which is nearly the capacity of our available service.

The National Electrical Code (NEC) requires that proper motor starting equipment be installed rated for the full load current. This includes appropriately rated motor contactors, wire, and circuit breakers. Circuit breakers have a “curve”, which relates to the kind of equipment they are meant to protect. A breaker rated for starting a large induction motor, for example, will take longer to trip than one rated for computer equipment, as the induction motor will experience a large overcurrent each time it starts. Use of a circuit breaker rated for motor starting on a room full of computers may not adequately protect the wires in the room if a fault condition exists, and use of a computer room type circuit breaker on a large motor starting circuit would trip every time the motor was started, assuming the circuit breaker’s amp rating is the same in both cases.

The breakers at the farm were verified to be the appropriate curve, and a similar sized motor was running off this circuit originally operating a now-abandoned part of the farm’s manure scraper system. On startup, our manure pump consumed very nearly 23.5 amps, as was verified by measurements. The problem was how to keep the combined load of the heater system, control overhead, and other systems from exceeding the available electrical supply. In order to facilitate this, it was decided that the operation of the manure system would supercede the other equipment on the digester.

Therefore, whenever the system mixed or fed, the water heater and pump were deactivated to free up their current for use by the manure system. There has been interest in operating large digester loads during “off peak” electrical hours. However, this supposes that it is a good idea to operate all loads of a digester at the same time. In the case of the Clarkson digester, operating in this way would have more than doubled our peak load, from around 25 amps to nearly 60. On a large digester with 30 HP pumps, this could require electrical service for the digester increasing from 15 kVA, which is the max of the single large pump and other small control loads, to 30 kVA or more. As a general reference, 24 kVA is about the same size as a standard domestic home electrical service.

The basic control loop of the manure handling system is illustrated in Figure 3.3. This figure illustrates the effect of “semi-automatic operation”, which was what was performed for feeding, and “automatic operation”, which is how the system operated unless the Feed On push button was operated. The feed interval and mix interval were entered into the system via the LCD control interface by the operator filling in the sentence “Mix tank every xxx minutes for yyy seconds”, where valid ranges for xxx and yyy were from 0 to 1024. This setting was changed over the summer, to compensate for various feeding schedules.

It was learned through operation of the summer that counters are needed as well. In order to ascertain if the feeding schedule is proceeding as planned, and that equipment is running as it should, the total pump run time and number of pump cycles performed under manual control needs to be recorded. Having a running tally of total pump run time plus number of pump start and stops would have made load calculation much easier. In addition, keeping track of total pump run time is essential for planning maintenance on rotating equipment like pumps, whose maintenance and lubrication intervals are typically specified in terms of hours of operation.

In addition to the control flow illustrated in Figure 3.3 there were also manual operations required to operate valves to feed the system. This was why the semi-automatic feeding operating was installed. As the system went through its design phases, originally it was planned to automatically feed from some storage vessel or hopper. Making the feeding fully automatic is easy from the control, but very difficult from the balance of plant and cost point of view for the size of the pilot plant. Adding automatic feeding would have required an extra pump, or automatic valves, which in itself would have been doable. What made it impossible was the need to characterize flows and mass balance for the sand separation experiments taking place. Metering sand density, mass, and other parameters, while also taking samples for lab analysis, is far beyond the scope of what would be required for commercial operation of a farm-based digester. However, the manner the system was fed was still valid, and could be employed instead of using a separate pump to feed the tank.