Work on the UNSW Sunswift II and III Solar Cars.

Perhaps the best engineering experience I have thus far had was the year I spent abroad in Australia working far too hard on the University of New South Wales Sunswift II and Sunswift III solar cars. I went abroad primarily for this reason. U of I had canceled their solar car project in 2000, the year that I ended up getting into the school, and I always wanted to work on a solar car. This was a project that involved a lot of people doing all sorts of different jobs, putting in long hours because the people were fun and the project interesting. While on this team, I helped solder solar arrays, troubleshoot and assemble maximum power point trackers, do carbon fiber layup, research and write mold release procedures, call up people to raise money, answer questions at trade shows, and other tasks. Oddly enough, at one point I found the U of I's Photon Torpedo in the dumpster, minus all the important bits. Somewhere there are some photos of me driving around with this thing tied onto the back of my pickup truck, but I don't know where they are.

This is is a photo of the Race Team for World Solar Challenge 2003. There were

many other people on the team than this; We just lucked out to be the ones who

got to go on the race. From left to right, me, Lauren, Rob, Owen, Pavel, Andrew,

Dave, Bonne, Blenno, and Ryan. We are standing over the actual Sunswift II at

the launch party. I am in the front of the picture because I did not wear the

right style of pants. Everyone else was wearing black slacks, and I show up in

jeans. Oops. The very friendly and nice photographer suggested I kneel, and

so it is forever recorded in this picture.

This is is a photo of the Race Team for World Solar Challenge 2003. There were

many other people on the team than this; We just lucked out to be the ones who

got to go on the race. From left to right, me, Lauren, Rob, Owen, Pavel, Andrew,

Dave, Bonne, Blenno, and Ryan. We are standing over the actual Sunswift II at

the launch party. I am in the front of the picture because I did not wear the

right style of pants. Everyone else was wearing black slacks, and I show up in

jeans. Oops. The very friendly and nice photographer suggested I kneel, and

so it is forever recorded in this picture.

One of the most important things about design teams, that I have missed in

recent projects after this, is the going out to get sloshed end of it. Every week,

following the team meeting, we would all rock up to The Reg and order potato wedges and beers

(Fosters is NOT Australian for beer), and talk about issues. Many important design decisions

with regard the solar cars were made at the bar. It is very nice to work long hours

with people if there is also a sitting around and drinking aspect. Work still

gets done, just in a different environment than the shop. A lot of people seem to

underestimate the importance of getting out of the shop and relaxing a bit.

One of the most important things about design teams, that I have missed in

recent projects after this, is the going out to get sloshed end of it. Every week,

following the team meeting, we would all rock up to The Reg and order potato wedges and beers

(Fosters is NOT Australian for beer), and talk about issues. Many important design decisions

with regard the solar cars were made at the bar. It is very nice to work long hours

with people if there is also a sitting around and drinking aspect. Work still

gets done, just in a different environment than the shop. A lot of people seem to

underestimate the importance of getting out of the shop and relaxing a bit.

The battery problem, one of many problems that we worked through. We had new packs

made for the race, and used them as little as possible during testing to make sure

we did not wear them out. Unfortunately, we noticed them draining faster than they

should have while we were doing the final testing. It turns out that they were assembled

with the wrong kind of tabbing. This means that the battery internal connections were

getting hotter than they should, which did not register on any of our telemetry

equipment. We spent the night before we left ripping the tabbing off, and then

driving around like crazy getting new tabbing put on the next day. The folks at the

battery shop were very helpful to use in this regard.

The battery problem, one of many problems that we worked through. We had new packs

made for the race, and used them as little as possible during testing to make sure

we did not wear them out. Unfortunately, we noticed them draining faster than they

should have while we were doing the final testing. It turns out that they were assembled

with the wrong kind of tabbing. This means that the battery internal connections were

getting hotter than they should, which did not register on any of our telemetry

equipment. We spent the night before we left ripping the tabbing off, and then

driving around like crazy getting new tabbing put on the next day. The folks at the

battery shop were very helpful to use in this regard.

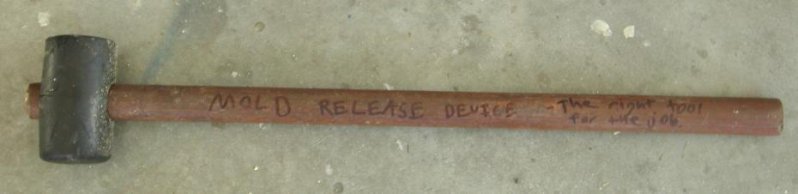

At one point, I was the Mechanical Team Leader, and as part of this, I was

doing research on making the tooling for the parts of the solar car. This was an

experiment in making a cast positive from an existing tooling mold. This tool was

never used, but the knowledge gained from this mess was instrumental in understanding

gel coats and tool making. Eventually I produced a mold release handbook, that

includes the steps to make the tooling negatives, and the treatment of these tools

to make them stable and suitable for carbon fiber work in the Boeing/Hawker De Haviland autoclaves.

At one point, I was the Mechanical Team Leader, and as part of this, I was

doing research on making the tooling for the parts of the solar car. This was an

experiment in making a cast positive from an existing tooling mold. This tool was

never used, but the knowledge gained from this mess was instrumental in understanding

gel coats and tool making. Eventually I produced a mold release handbook, that

includes the steps to make the tooling negatives, and the treatment of these tools

to make them stable and suitable for carbon fiber work in the Boeing/Hawker De Haviland autoclaves.

We also had a lot of mistakes happen while doing work on the tooling. We were working with

making expanding foam tools as a way to make plugs from other parts. Tool making involves

starting with a plug, made in our case by CNC machining. A mold is then made from this plug

that will stand up to the rigors of carbon fiber work and handling. Making molds involves

putting down a release agent on the plug, then a gel coat, then building up progressive

layers of material. Finally, a filler or very coarse material is used to make a structural

back, to make the mold flex as little as possible when it is handled and used. This particular

photo shows us experimenting with release agents (in our case Zyvax, which is really awesome

water based stuff) and expanding foam. Someone had sanded the tool without letting us know,

and we went and poured expanding foam in. When the process works, the mold pops off the plug

with a simple wack from the big hammer shown at the top of the page. The results of this

experimentation were used in making the tooling for Sunswift III.

We also had a lot of mistakes happen while doing work on the tooling. We were working with

making expanding foam tools as a way to make plugs from other parts. Tool making involves

starting with a plug, made in our case by CNC machining. A mold is then made from this plug

that will stand up to the rigors of carbon fiber work and handling. Making molds involves

putting down a release agent on the plug, then a gel coat, then building up progressive

layers of material. Finally, a filler or very coarse material is used to make a structural

back, to make the mold flex as little as possible when it is handled and used. This particular

photo shows us experimenting with release agents (in our case Zyvax, which is really awesome

water based stuff) and expanding foam. Someone had sanded the tool without letting us know,

and we went and poured expanding foam in. When the process works, the mold pops off the plug

with a simple wack from the big hammer shown at the top of the page. The results of this

experimentation were used in making the tooling for Sunswift III.

Another extremely annoying part of doing tooling is getting a quality gel coat.

The gel coat is what ends up being the tooling surface that eventually ends up

being the outside surface of your finished part. The gel coat needs to be entirely

free of air bubbles, cracks, and surface imperfections. Any surface issues in the

gel coat will get into the finished part, which could create problems from release

issues to structural problems to mere blemishes. In this picture, Scott is removing

a botched gel coat from one of our plugs. The function of the Zyvax is seen here.

The gel coat is easily cracking off the surface, which shows the release agent

actually worked.

Another extremely annoying part of doing tooling is getting a quality gel coat.

The gel coat is what ends up being the tooling surface that eventually ends up

being the outside surface of your finished part. The gel coat needs to be entirely

free of air bubbles, cracks, and surface imperfections. Any surface issues in the

gel coat will get into the finished part, which could create problems from release

issues to structural problems to mere blemishes. In this picture, Scott is removing

a botched gel coat from one of our plugs. The function of the Zyvax is seen here.

The gel coat is easily cracking off the surface, which shows the release agent

actually worked.

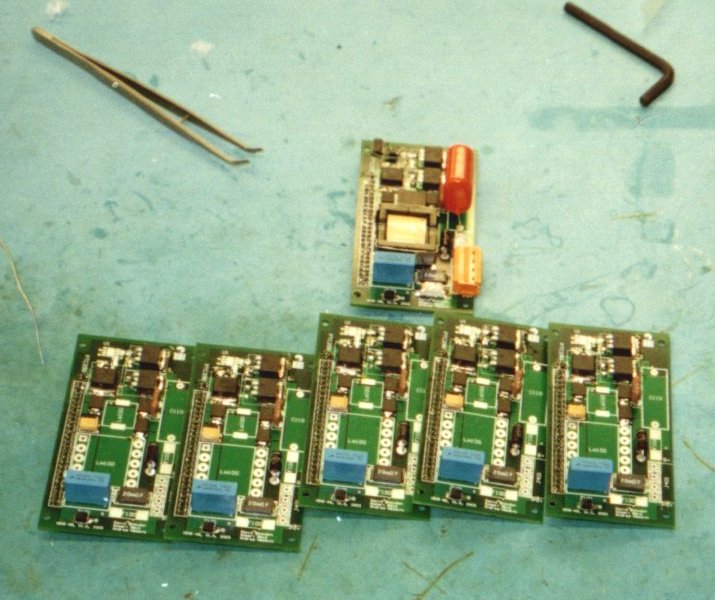

I volunteered to assemble a whole slew of maximum power point tracker boards,

my first SMT assembly gig. This was a design project done by Rob. All I did was put

together a bunch of these, and lent a small amount of help in debugging them.

It turns out that there was a communications mistake with these boards, and

the schematics that were used to lay out the PCB's were not up to date with

the debugging copies that Rob was working with, which meant all the boards were wrong.

These devices eventually were made functional, but not in time to be used in Sunswift II.

I volunteered to assemble a whole slew of maximum power point tracker boards,

my first SMT assembly gig. This was a design project done by Rob. All I did was put

together a bunch of these, and lent a small amount of help in debugging them.

It turns out that there was a communications mistake with these boards, and

the schematics that were used to lay out the PCB's were not up to date with

the debugging copies that Rob was working with, which meant all the boards were wrong.

These devices eventually were made functional, but not in time to be used in Sunswift II.

In the time immediately before we left for the WSC '03, the race team slept out at

Solarch. This was to get used to roughing it, bond as a team, and be available to

be extra hard-core to get stuff done on time. Solarch was once a grand and

awesome example of sustainable architecture, complete with a big PV array,

lots of windows, passive heating/cooling, and environmentally friendly materials.

Unfortunately, some design issues were overlooked, and I believe UNSW would

rather forget about Solarch. That being said, it made a great place to work on

the Solar Car, even if it was broken into every few weeks. Blenno and I rocked up

under this little conference room at the back of Solarch with the swags.

Just a few hundred feet away was a beach, so not a bad place to camp out at all.

In the time immediately before we left for the WSC '03, the race team slept out at

Solarch. This was to get used to roughing it, bond as a team, and be available to

be extra hard-core to get stuff done on time. Solarch was once a grand and

awesome example of sustainable architecture, complete with a big PV array,

lots of windows, passive heating/cooling, and environmentally friendly materials.

Unfortunately, some design issues were overlooked, and I believe UNSW would

rather forget about Solarch. That being said, it made a great place to work on

the Solar Car, even if it was broken into every few weeks. Blenno and I rocked up

under this little conference room at the back of Solarch with the swags.

Just a few hundred feet away was a beach, so not a bad place to camp out at all.

One of the other things I really enjoyed doing is explaining stuff to people.

On the way to the start of WSC, we stopped at towns along the way, set up in parks,

rolled out the car, and stood around to field questions and talk about how neat

solar energy is. We also managed space at CeBIT Australia, NRMA apppearances, and others.

I heard a lot of people ask a lot of very good questions. In retrospect, these

opportunities were among the more valuable parts of this experience,

given my current recurring interest in solar power.

One of the other things I really enjoyed doing is explaining stuff to people.

On the way to the start of WSC, we stopped at towns along the way, set up in parks,

rolled out the car, and stood around to field questions and talk about how neat

solar energy is. We also managed space at CeBIT Australia, NRMA apppearances, and others.

I heard a lot of people ask a lot of very good questions. In retrospect, these

opportunities were among the more valuable parts of this experience,

given my current recurring interest in solar power.

Whenever I have my camera and a group of people, I feel compelled to have everyone

point in a picture. This particular photo was at a school in Longreach during one

of our Q and A stops. This is what the Sunswift II chassis looks like without the

array mounted. The Sunswift III is a monocoque design, which means it gets

all its strength from carbon fiber structural elements, rather than

Sunswift II's welded metal frame.

Whenever I have my camera and a group of people, I feel compelled to have everyone

point in a picture. This particular photo was at a school in Longreach during one

of our Q and A stops. This is what the Sunswift II chassis looks like without the

array mounted. The Sunswift III is a monocoque design, which means it gets

all its strength from carbon fiber structural elements, rather than

Sunswift II's welded metal frame.

Unfortunately, we never made it to WSC. There was an accident that killed our

poor Sunswift II. This photo was taken in lovely Winton. Sunswift II is

right behind the person taking the picture. It was kind of a sad day, with

certain team members taking it harder than others. Some members went on to WSC

and helped out other teams on their own accord. Some of us flew back to UNSW,

and the rest of us drove the remaining undamaged cars back to UNSW. After some

time of mourning, the team went right back into designing the UNSW Sunswift III.

Unfortunately, we never made it to WSC. There was an accident that killed our

poor Sunswift II. This photo was taken in lovely Winton. Sunswift II is

right behind the person taking the picture. It was kind of a sad day, with

certain team members taking it harder than others. Some members went on to WSC

and helped out other teams on their own accord. Some of us flew back to UNSW,

and the rest of us drove the remaining undamaged cars back to UNSW. After some

time of mourning, the team went right back into designing the UNSW Sunswift III.