The RF Tester @ Fermi National Accelerator Lab

I was luckily able to work at Fermi National Accelerator Laboratory for a few summers while studying engineering at U of I. During my summers there, I was working on the NLC project, mostly for Gennady Romanov, a very talented man who was working closely with the design of non superconducting (warm) accelerating structures. The accelerating structures, each on the order of 1 meter long, were comprised of stacks of precision machined disks. These disks were stacked up and bonded together, and then theoretically used to accelerate particles. Producing the disks and the structures were very tricky, involving insane amounts of calculation and truly tiny tolerances.

One of the things I was tasked with was figuring out a better QC system to facilitate testing and sorting. Testing these disks involved placing them between two antenna blocks and then applying a constant load, meant to simulate their behavior in the finished stack. A spectrum analyzer was then used to measure its frequency responses to several different modes important to the nontrivial task of making very tiny things go very very fast. The machine originally used to do this involved a stack of weights on a hinge, and a great big knob on top to apply pressure. This machine was labor intensive to use, and the testing was operator dependent. The amount of force applied was proportional to how hard the operator turned the crank, until the peaks looked about right. This was not repeatable operator-to-operator, so a better solution had to be found.

The first thought I had, with the goal of repeatable, known pressure was

a pneumatic piston. There was a very nice, clean, filtered air source in the

clean room in which we were operating. I ordered some parts, headed into

the basement, and starting knocking stuff together. This project took nearly

two months, including a week of me cranking through a big book on AutoCad

to learn how to make drawings that the machinists wouldn't laugh at. The

folks in the Technical Divisions' engineering department helped me out a lot

on the mechanics of this. The first revision is shown here, testing the T

joint used to get the power into the structure. The box at left was all

made in the basement, and all the shiny nice metal at right made at the

machine shop at Fermilab's Technical Division. The original idea was that

the air pressure would be good enough to tell the force felt by the disk,

but Gennady wanted a load cell, so I added the load cell. He was right.

It makes it much better. The force of the piston is changed by the

black knob, and the down and up buttons do what you would think. Out the top

are two gages reading pressure in the line and pressure in the cylinder.

The first thought I had, with the goal of repeatable, known pressure was

a pneumatic piston. There was a very nice, clean, filtered air source in the

clean room in which we were operating. I ordered some parts, headed into

the basement, and starting knocking stuff together. This project took nearly

two months, including a week of me cranking through a big book on AutoCad

to learn how to make drawings that the machinists wouldn't laugh at. The

folks in the Technical Divisions' engineering department helped me out a lot

on the mechanics of this. The first revision is shown here, testing the T

joint used to get the power into the structure. The box at left was all

made in the basement, and all the shiny nice metal at right made at the

machine shop at Fermilab's Technical Division. The original idea was that

the air pressure would be good enough to tell the force felt by the disk,

but Gennady wanted a load cell, so I added the load cell. He was right.

It makes it much better. The force of the piston is changed by the

black knob, and the down and up buttons do what you would think. Out the top

are two gages reading pressure in the line and pressure in the cylinder.

Another view of the first revision, from the back. The original thought involved

a more user-friendly finger/disk interface. The small piston on the far right

was going to be something that slid a little shelf in and out, and the C-clamped

switch on top was going to make the main piston go up and down. This idea failed

due to lack of time. In order to get it done in the time I had, I needed to stop

fooling with CAD models and get the thing built. It was in this configuration that

the research group used this machine for the better part of a year, testing all

the disks and couplers that came through the lab.

Another view of the first revision, from the back. The original thought involved

a more user-friendly finger/disk interface. The small piston on the far right

was going to be something that slid a little shelf in and out, and the C-clamped

switch on top was going to make the main piston go up and down. This idea failed

due to lack of time. In order to get it done in the time I had, I needed to stop

fooling with CAD models and get the thing built. It was in this configuration that

the research group used this machine for the better part of a year, testing all

the disks and couplers that came through the lab.

The downside of this device was the heinously small box and overzealous use of tiny

tubes. This was my first project using pneumatics, and I got a little ahead of

myself, creating a pipe leak center that only 1970's engine designers could have beat.

In the center are the two valves that operated the up-and-down piston and what was

supposed to be the slide in-and-out piston. At right are the flow restrictors to

keep the pistons from slamming up and down too quickly. At the top is the control

pressure regulator, which regulated the line air down to a pressure for the pushbuttons

and air sensors. At the lower left is the main regulator, which was a piece of equipment

from my father's stock of air tools in the basement. The bundle of hoses to the valve and

the main on/off switch is seen at the lower right. This mess of tubes, a classic example

of 10 pounds of crap in a 5 pound bag, did exactly what it should, to the annoyance of

the people who used it- Since it was designed to operate two pistons, the operator

needed to push the green button on the front, then push the little detector switch

at the top, which would cause the pressure piston to go down.

The downside of this device was the heinously small box and overzealous use of tiny

tubes. This was my first project using pneumatics, and I got a little ahead of

myself, creating a pipe leak center that only 1970's engine designers could have beat.

In the center are the two valves that operated the up-and-down piston and what was

supposed to be the slide in-and-out piston. At right are the flow restrictors to

keep the pistons from slamming up and down too quickly. At the top is the control

pressure regulator, which regulated the line air down to a pressure for the pushbuttons

and air sensors. At the lower left is the main regulator, which was a piece of equipment

from my father's stock of air tools in the basement. The bundle of hoses to the valve and

the main on/off switch is seen at the lower right. This mess of tubes, a classic example

of 10 pounds of crap in a 5 pound bag, did exactly what it should, to the annoyance of

the people who used it- Since it was designed to operate two pistons, the operator

needed to push the green button on the front, then push the little detector switch

at the top, which would cause the pressure piston to go down.

The following summer I came back again, this time with some more sense about me.

I was impressed that Gennady and the folks at this part of the NLC group were using

the thing, and they decided they liked it and wanted a better, more robust, and

less messy version. The metal bits on the right are mainly the same- They built

more antenna blocks and adapters to test different kinds of things, but the overall

function remained the same. First thing I did was throw out the stuff that did not

work on the previous version. This included the extra slide feature, which was

deemed not worth the effort. The control box now features the Sensotec load cell

readout on board, and a simple one-handed back and forth knob to control the

operation of the force applier. There are also instructions printed on a nice

laminated sheet, riveted on to the front of the chassis. The gages across the front

read incoming line, control, and cylinder pressures. The big black knob still sets

the applied force. There is that tiny switch on the right, which is the main air

on/off switch. The green indicator tells that operator that the system is pressurized,

and the black knob makes the cylinder go up and down. The system was typically set to

apply around 300 lbs of pressure to the disks under test. Using the lab air supply,

the system operated effectively from 50 lbs up to about 500 lbs, at which point

the aluminum cross at the top would start deflecting alarmingly.

The following summer I came back again, this time with some more sense about me.

I was impressed that Gennady and the folks at this part of the NLC group were using

the thing, and they decided they liked it and wanted a better, more robust, and

less messy version. The metal bits on the right are mainly the same- They built

more antenna blocks and adapters to test different kinds of things, but the overall

function remained the same. First thing I did was throw out the stuff that did not

work on the previous version. This included the extra slide feature, which was

deemed not worth the effort. The control box now features the Sensotec load cell

readout on board, and a simple one-handed back and forth knob to control the

operation of the force applier. There are also instructions printed on a nice

laminated sheet, riveted on to the front of the chassis. The gages across the front

read incoming line, control, and cylinder pressures. The big black knob still sets

the applied force. There is that tiny switch on the right, which is the main air

on/off switch. The green indicator tells that operator that the system is pressurized,

and the black knob makes the cylinder go up and down. The system was typically set to

apply around 300 lbs of pressure to the disks under test. Using the lab air supply,

the system operated effectively from 50 lbs up to about 500 lbs, at which point

the aluminum cross at the top would start deflecting alarmingly.

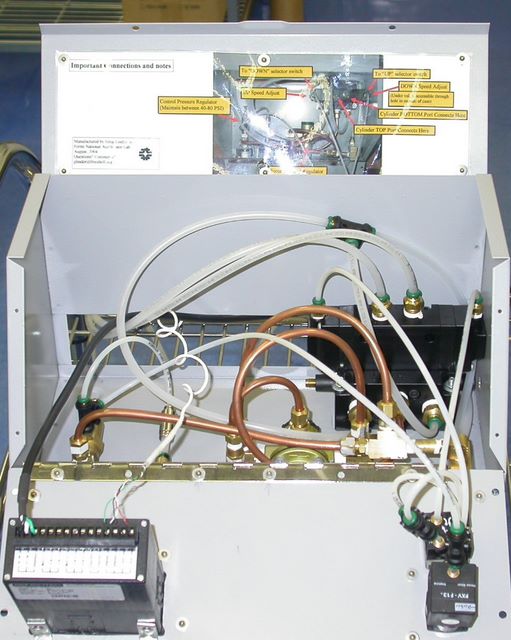

This is what the box looks like inside. I decided to user copper for tubing that did

not need to leave the box. This not only makes the thing look cooler, but it also helps

to minimize tubing clutter. There is also a new valve block in here. Rather than using

the valves in the previous version, I chose to use a bussed device with internal flow

restriction. This was done as a measure of making things look better and be more stable

and less leak-prone. The other valving solution had more air connections and threaded

bits. The valve block is the black unit at the right side of the picture. The flow

restriction adjustment screws can be seen sticking out to the lower left and lower

right on the valve block. The right hand adjustment screw is accessed via a hole in

the side of the case. The main air line regulator is seen with the two large swooping

copper tubes. The control switch and indicator is at the lower right, with the back

of the Sensotec readout at the lower left. Because I knew that I would most likely

never be back to repair this thing, I riveted a color photo with all the parts

labeled inside the top cover.

This is what the box looks like inside. I decided to user copper for tubing that did

not need to leave the box. This not only makes the thing look cooler, but it also helps

to minimize tubing clutter. There is also a new valve block in here. Rather than using

the valves in the previous version, I chose to use a bussed device with internal flow

restriction. This was done as a measure of making things look better and be more stable

and less leak-prone. The other valving solution had more air connections and threaded

bits. The valve block is the black unit at the right side of the picture. The flow

restriction adjustment screws can be seen sticking out to the lower left and lower

right on the valve block. The right hand adjustment screw is accessed via a hole in

the side of the case. The main air line regulator is seen with the two large swooping

copper tubes. The control switch and indicator is at the lower right, with the back

of the Sensotec readout at the lower left. Because I knew that I would most likely

never be back to repair this thing, I riveted a color photo with all the parts

labeled inside the top cover.

Here's what the parts looked like on the bench in the basement of the Linder House.

Originally, the front of this box was one piece that screwed on. I needed to make

it hinged so I could have the top fold open, as shown in the previous picture.

This took a lot of hack-sawing and filing, but I think the results are quite

practical and useful. Once the unit is put together, all the hoses and fittings

can be got at without taking the front of the thing apart. This was the first

project I did using a chassis punch (or "slug buster"), which I now acknowledge as

one of the best innovations in the universe. Also the first for worrying about

copper line for pressurized air. After I left Fermilab, this rig

was used to measure superconducting structures, as the NLC steering committee

decided that the "high temp" solution (copper) was not the way they were going to go.

I should see if they are still using this equipment.

Here's what the parts looked like on the bench in the basement of the Linder House.

Originally, the front of this box was one piece that screwed on. I needed to make

it hinged so I could have the top fold open, as shown in the previous picture.

This took a lot of hack-sawing and filing, but I think the results are quite

practical and useful. Once the unit is put together, all the hoses and fittings

can be got at without taking the front of the thing apart. This was the first

project I did using a chassis punch (or "slug buster"), which I now acknowledge as

one of the best innovations in the universe. Also the first for worrying about

copper line for pressurized air. After I left Fermilab, this rig

was used to measure superconducting structures, as the NLC steering committee

decided that the "high temp" solution (copper) was not the way they were going to go.

I should see if they are still using this equipment.