Meter Retrofit Work: When KYZ Is Not Enough

Most engineers spend a lot of time in front of computers. In my case, much of this work involves sitting in front of a computer mapping datapoints, managing SCADA networks and servers, making spreadsheets, and assistanting in remote debugging. Turns out that I am lucky enough to work closely with people in the field, and get to go on-site to perform very unique tasks several times a year. In this case, one of those occasions was to install PQM (Power Quality Meters) at one of our sites, to compliment the KYZ billing meter interfaces we already had available.

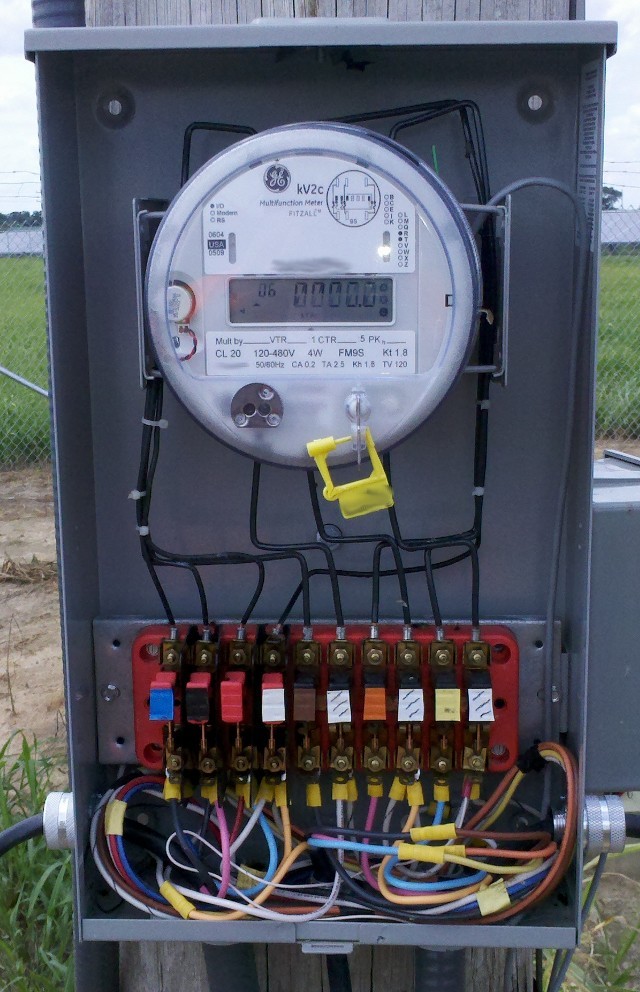

Here is our basic electric meter for the site. This particular site has two of these meters, one for each of the medium voltage distribution lines taking power from the site. The task was to tap the voltage sense and current sense cabling from the existing meter and bring them into our temporary PQM equipment. This shows Meter A. The flexible cables coming through the weatherproof glands are for the CT (Current Transformer) and VT (Voltage Transformer) signals. We had the support of the City for doing this, with me performing low voltage work and the City's meter tech performing the interconnect inside their meter enclosures.

Here is our basic electric meter for the site. This particular site has two of these meters, one for each of the medium voltage distribution lines taking power from the site. The task was to tap the voltage sense and current sense cabling from the existing meter and bring them into our temporary PQM equipment. This shows Meter A. The flexible cables coming through the weatherproof glands are for the CT (Current Transformer) and VT (Voltage Transformer) signals. We had the support of the City for doing this, with me performing low voltage work and the City's meter tech performing the interconnect inside their meter enclosures.

The meter data is available to the city via their AMR (Automatic Meter Reading) system, that feeds data into their billing system to generate billing statements for energy provided or consumed. The meter data comes into the plant SCADA System for kwh accounting purposes as an optically isolated KYZ pulse. A KYZ pulse is basically a relay that changes state every some number of kwh. That value is referred to as "K sub c" Kc, and is set according to the metering department of each utility that uses the meters. The grey box on the right hand side contains the isolation equipment for the KYZ pulse output of the meter. The KYZ signals are then counted up, and multiplied by Kc to show us the number of kwh recorded by the meter.

This is the inside of Meter A. At the top is a standard A-Base meter, a style of meter common throughout the commercial and residential metering world. At the bottom are test switches that allow the meter circuits to be de-energized(VTs) and shorted (CTs), thus making it safe for the meter to be removed. The City needed to splice in the wires to their existing meter leads, allowing our meters to measure the same signals. This lead to lots of butt splices (the yellow tubes) and double-stacking of fork terminals onto the test switches. The city in general was very helpful in getting this done, and we were able to get everything wired up in a hurry. The whole install took less than a day.

This is the inside of Meter A. At the top is a standard A-Base meter, a style of meter common throughout the commercial and residential metering world. At the bottom are test switches that allow the meter circuits to be de-energized(VTs) and shorted (CTs), thus making it safe for the meter to be removed. The City needed to splice in the wires to their existing meter leads, allowing our meters to measure the same signals. This lead to lots of butt splices (the yellow tubes) and double-stacking of fork terminals onto the test switches. The city in general was very helpful in getting this done, and we were able to get everything wired up in a hurry. The whole install took less than a day.

Why two sets of meters? This is because the utility meters are generally off-limits to the plant SCADA system, as the utility needs to keep them calibrated and secure, as they are optimized for billing purposes. The meters in the cases that were retrofit are referred to as check meters, and allow us to provide some amount of data back to the utility, for example, if a meter goes out of service. Additionally, the utility revenue meters do not support power quality functions. The check meters do, which allows the control center to check if a reported issue in another part of the plant is due to a line sag or swell, for example. The SEL-735's provide a great deal of data, and these are configured to grab a snapshot of the current and voltage measurements for later analysis. This feature has proven extremely useful, as it allows us to determine the effect that voltage fluctuations on the grid have on the inverters, or the effect the inverters have on the grid. Additionally, because the SEL-735's are on a real time link the plant SCADA systems, they can provide fast enough data to allow for real time grid control functionality, sometimes called voltage support or grid support functions.

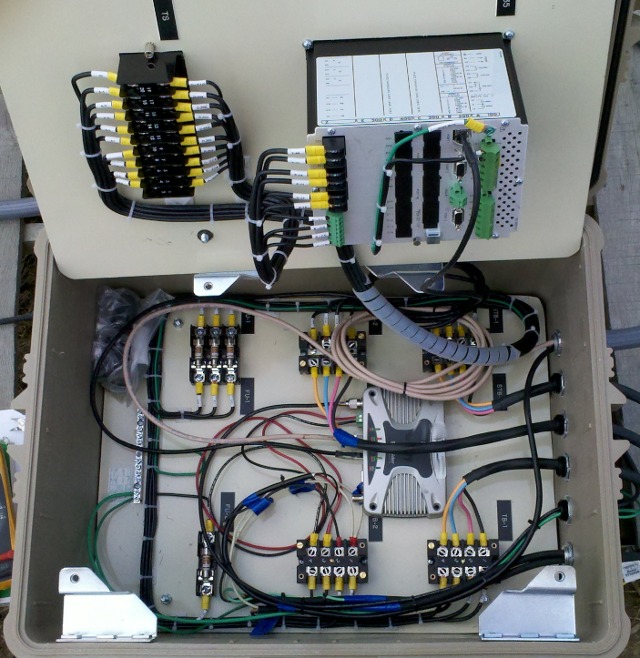

This is the PQM cabinet that reads Meter A. At the right of the box in the bottom is where the cables come in from the splices from the above picture. At the top of the frame are our test switches (at right) and the meter itself (at left). Having our test switches as well means that we can take our meter out of the circuit for maintenance or replacement without affecting the meter reads on the City's meters. In the base of the cabinet are fuse blocks for power and sense signals, as well as the data radio we use to get the meter data back to the SCADA Systems installed at the solar site itself. I performed meter configuration, terminations inside these cases, and (re)configuration of the SCADA equipment on-site to get the data out of the meters to the the control room.

This is the PQM cabinet that reads Meter A. At the right of the box in the bottom is where the cables come in from the splices from the above picture. At the top of the frame are our test switches (at right) and the meter itself (at left). Having our test switches as well means that we can take our meter out of the circuit for maintenance or replacement without affecting the meter reads on the City's meters. In the base of the cabinet are fuse blocks for power and sense signals, as well as the data radio we use to get the meter data back to the SCADA Systems installed at the solar site itself. I performed meter configuration, terminations inside these cases, and (re)configuration of the SCADA equipment on-site to get the data out of the meters to the the control room.

Here are the meters we installed, sitting on a pallet to keep them out of the mud. As a temporary install, it was decided to package the meters in re-usable outdoor cases, so we can ship them to another site once the task at this site is complete. All cable entries are sealed with cable glands,

so that the NEMA rating of the enclosures was preserved. Originally, this install was

supposed to last only a few months, until new distribution equipment was installed nearby.

The meters have been out there for more than two years, and it is great that we specified high quality

equipment for the (not so) temporary install.

Here are the meters we installed, sitting on a pallet to keep them out of the mud. As a temporary install, it was decided to package the meters in re-usable outdoor cases, so we can ship them to another site once the task at this site is complete. All cable entries are sealed with cable glands,

so that the NEMA rating of the enclosures was preserved. Originally, this install was

supposed to last only a few months, until new distribution equipment was installed nearby.

The meters have been out there for more than two years, and it is great that we specified high quality

equipment for the (not so) temporary install.

Portable when applied to utility-grae metering is a relative term. This is the luggage that I personally toated through the airport en route to the jobsite. At the top of the pil`e is my lappy, then my tools in the top bag, and then my clothes, PPE (Personal Protective Equipment), and work boots in the larger roller bag. Both those bags are siting on the meter cases, each of which is a smidge over SouthWest Airlines' bag weight limit. The total mass of tools and equipment I hauled through the airport for this job was just over 200 lbs.

Portable when applied to utility-grae metering is a relative term. This is the luggage that I personally toated through the airport en route to the jobsite. At the top of the pil`e is my lappy, then my tools in the top bag, and then my clothes, PPE (Personal Protective Equipment), and work boots in the larger roller bag. Both those bags are siting on the meter cases, each of which is a smidge over SouthWest Airlines' bag weight limit. The total mass of tools and equipment I hauled through the airport for this job was just over 200 lbs.

Not just that, but this trip turned into what I call an East Coast Razmatazz, where I visit multiple sites in relative close proximity on the east side of the US. I lugged these meter cases through several different places before getting to the site where they were to be installed. Next time I will ship them to a nearby hotel, ahead of time. I did find, however, that nothing says Serious Business like showing up a hotel with a bunch of military-colored roller cases.