Logan Model 200 Turret Lathe

When I was in High School, my father bought some tools from a friend of his that was getting out of the machine shop business. As part of this, he got a really good deal on a Logan Lathe and a drill press. The Logan was in very good shape. The drill press slightly less so, as the spindle bearings were in very poor shape. I was in high school at the time, and used these machines to teach myself basic lathe and drill press operation. The drill press was in bad shape and was scrapped a few years after we got it. The Lathe, however, served me well for several tinkering sessions, as was eventually sold to a collector of such equipment when I moved out of St. Charles. I really wanted to hold onto it, but alas, what does a college guy do with a 700 lb lathe? This machine actually got sold in 2006, but it is mentioned pre 2000, as that is when I was able to get the most use out of it.

Here's a front view of the Logan. This particular machine was from 1937, had a flat belt drive, and needed new pulleys, a new motor and wiring, and a good cleaning and greasing. Also with this lathe was an almost complete set of collets and a bunch of extra tool tips. This machine came with its turret. I never set it up, but the turret stayed with the machine into its home. I have no idea, in retrospect, how we get this downstairs. It was me and a girl I was dating in high school, who probably weighed 120 lbs soaking wet. We shlepped this down the stairs and I put it up on its legs myself at night. There real is nothing like the power of simple machines. At this point I have moved all sorts of crazy stuff on rollers and ramps, but the lathe was one of the first. I've always wanted to build a steam engine, but never got the time while I had the tools. At some point when I get my shop, I'll go back out on the prowl for vintage machine tools.

Here's a front view of the Logan. This particular machine was from 1937, had a flat belt drive, and needed new pulleys, a new motor and wiring, and a good cleaning and greasing. Also with this lathe was an almost complete set of collets and a bunch of extra tool tips. This machine came with its turret. I never set it up, but the turret stayed with the machine into its home. I have no idea, in retrospect, how we get this downstairs. It was me and a girl I was dating in high school, who probably weighed 120 lbs soaking wet. We shlepped this down the stairs and I put it up on its legs myself at night. There real is nothing like the power of simple machines. At this point I have moved all sorts of crazy stuff on rollers and ramps, but the lathe was one of the first. I've always wanted to build a steam engine, but never got the time while I had the tools. At some point when I get my shop, I'll go back out on the prowl for vintage machine tools.

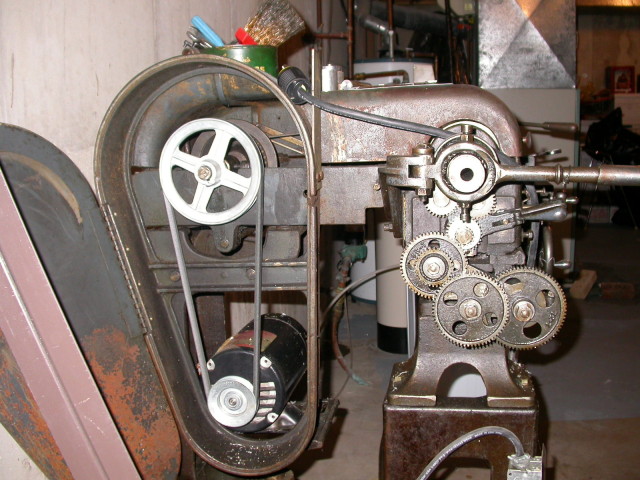

The headstock end of the Logan. Immediately apparent is the newer motor and pulleys, as well as the bar feed and gear train. I had a cover for the gear train, but I never installed it. I appreciate a lot what I learned about safety from this machine, knowing that when it was on there was any number of shirt-eating spinning gears inches away from your hands. For those of you who routinely center with four-jaw independent chucks, I salute you. It was the only chuck I had, but like working an analog o-scope without the auto set button, being able to center with one of those chucks is an important bit of time-honored tradition.

The headstock end of the Logan. Immediately apparent is the newer motor and pulleys, as well as the bar feed and gear train. I had a cover for the gear train, but I never installed it. I appreciate a lot what I learned about safety from this machine, knowing that when it was on there was any number of shirt-eating spinning gears inches away from your hands. For those of you who routinely center with four-jaw independent chucks, I salute you. It was the only chuck I had, but like working an analog o-scope without the auto set button, being able to center with one of those chucks is an important bit of time-honored tradition.