The Digester: Gas Measurement System

Despite the fact that I attended Clarkson to research control systems for distributed renewable energy systems, someone needed to fix the gas system. When I first arrived, no one had given any thought to metering or pressure regulation. There was a flare, and a pipe going from the tank to the flare, but using this we would not have been able to regulate the tank pressure to keep it anaerobic. We also would not have been able to measure anything, and we needed to measure methane concentration and flow rate.

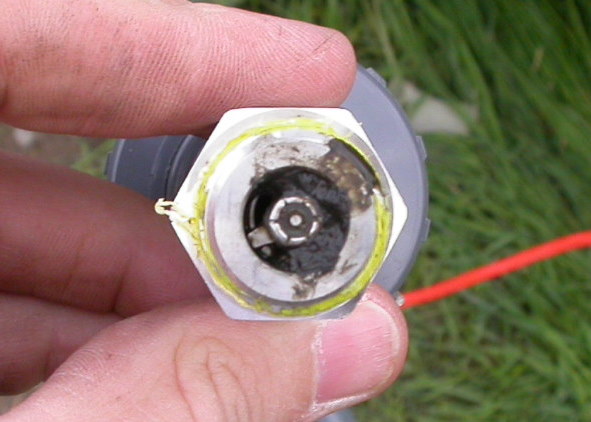

The initial solution, as suggested by another grad student: A check valve. This picture shows a check valve, after being installed in the tank for a few weeks. Notice, that not only is the check valve caked in solids, but also, it would have never worked in the first place. A check valve is not designed to regulate pressure. In fact, the use of this solution emptied our tank by not fully opening at its crack pressure, which is to be expected operating these style of valves at a low pressure / low flow situation. The valve would open enough to hiss, but the pressure would build up enough to drain the tank before it opened the valve the rest of the way. The next solution: A back pressure regulator.

The initial solution, as suggested by another grad student: A check valve. This picture shows a check valve, after being installed in the tank for a few weeks. Notice, that not only is the check valve caked in solids, but also, it would have never worked in the first place. A check valve is not designed to regulate pressure. In fact, the use of this solution emptied our tank by not fully opening at its crack pressure, which is to be expected operating these style of valves at a low pressure / low flow situation. The valve would open enough to hiss, but the pressure would build up enough to drain the tank before it opened the valve the rest of the way. The next solution: A back pressure regulator.

After much research finding a commercially available back pressure regulator that would work at 8 3/8 inches of water and 0.02 SCFM, I decided to do it the old fashioned way. At right in the photo is the back pressure regulator I built, which is nothing more than a 5 gallon water tank with a pipe going down the center. At the left hand side of the photo is a standard American Meter natural gas meter, and then a blue box with a wire attached to it. That blue box reads volumetric percent methane. The BlueSens methane sensor outputs 5-20 mA for 0-100% methane, and the American Meter is fitted with a pulser that outputs 1 pulse per 2 cubic feet. Just before the methane sense tee, there is a low budget transparent check valve. This was installed so that when we turned on the gas blower, the suction created would not try and suck the fluid out of the back pressure regulator. It requires no forward pressure to open, as the rubber seat naturally deforms enough to keep the valve open even when no pressure is applied.

After much research finding a commercially available back pressure regulator that would work at 8 3/8 inches of water and 0.02 SCFM, I decided to do it the old fashioned way. At right in the photo is the back pressure regulator I built, which is nothing more than a 5 gallon water tank with a pipe going down the center. At the left hand side of the photo is a standard American Meter natural gas meter, and then a blue box with a wire attached to it. That blue box reads volumetric percent methane. The BlueSens methane sensor outputs 5-20 mA for 0-100% methane, and the American Meter is fitted with a pulser that outputs 1 pulse per 2 cubic feet. Just before the methane sense tee, there is a low budget transparent check valve. This was installed so that when we turned on the gas blower, the suction created would not try and suck the fluid out of the back pressure regulator. It requires no forward pressure to open, as the rubber seat naturally deforms enough to keep the valve open even when no pressure is applied.

A view of the gas metering system at the top of the tank. The gas system measuring components were all heater traced to maintain the gas and measurement components above the dew point of the gas. Otherwise, we ran a risk of our American Meter from filling up with water and affecting our measurement. The LED display on the methane sensor in this case reads 58.1 % methane. Visible in this photo is the mess of 3 / 4 inch pipe, gas blower pipes, and heater lines that made this tank top such a delight to work on.

A view of the gas metering system at the top of the tank. The gas system measuring components were all heater traced to maintain the gas and measurement components above the dew point of the gas. Otherwise, we ran a risk of our American Meter from filling up with water and affecting our measurement. The LED display on the methane sensor in this case reads 58.1 % methane. Visible in this photo is the mess of 3 / 4 inch pipe, gas blower pipes, and heater lines that made this tank top such a delight to work on.

This is the back pressure regulator installed just next to the flare. The bottle was filled with 5 inches of RV alcohol-based antifreeze. The other 3 3/8 inches of head loss came from the head loss in the gas system itself. It was nice to have a transparent container for our gas pressure regulator, as it was easy to see when there was gas bubbling and how vigorously it bubbled.

This is the back pressure regulator installed just next to the flare. The bottle was filled with 5 inches of RV alcohol-based antifreeze. The other 3 3/8 inches of head loss came from the head loss in the gas system itself. It was nice to have a transparent container for our gas pressure regulator, as it was easy to see when there was gas bubbling and how vigorously it bubbled.