Future Energy Challenge 2004: Variable Frequency Motor Drive

![]() If you are one of those people that love Assembly, feel free to read

through the PIC18F assembly from the FEC motor drive by clicking on

the icon to the left.

If you are one of those people that love Assembly, feel free to read

through the PIC18F assembly from the FEC motor drive by clicking on

the icon to the left.

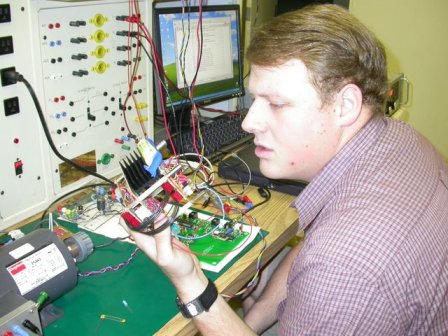

What do I do when I get back from Australia but decide that I want to

know what makes motors go in circles? Enter Future Energy Challenge 2004, a

design competition in which we were soundly trounced by the group from

the University of Belgrade, Serbia. I was in charge of

writing firmware for this project. This photo was taken during Engineering

Open House. On the bench are the PFC, inverter and control, and laptop. We

were spinning a the motor/dyno in the background with it during the whole

demonstration, explaining PWM to groups of pre-college students wandering

around. I really enjoy standing around satisfying other people's curiosity.

You never know when someone else's potentially uninformed question will

make your mind consider something differently. You also cannot ever fully

understand something without having to patiently explain it to someone else.

Like re-reading a paper out loud after it has been written, you pick up a

new understanding of something trying to convey a system's operation.

What do I do when I get back from Australia but decide that I want to

know what makes motors go in circles? Enter Future Energy Challenge 2004, a

design competition in which we were soundly trounced by the group from

the University of Belgrade, Serbia. I was in charge of

writing firmware for this project. This photo was taken during Engineering

Open House. On the bench are the PFC, inverter and control, and laptop. We

were spinning a the motor/dyno in the background with it during the whole

demonstration, explaining PWM to groups of pre-college students wandering

around. I really enjoy standing around satisfying other people's curiosity.

You never know when someone else's potentially uninformed question will

make your mind consider something differently. You also cannot ever fully

understand something without having to patiently explain it to someone else.

Like re-reading a paper out loud after it has been written, you pick up a

new understanding of something trying to convey a system's operation.

This is a picture of the FEC controls team. These five people were tasked with writing

the software that would make our home-grown variable frequency drive make a home

grown induction motor go in circles. VFD is how you change the speed of induction

motors. You cannot just change the voltage into them, as their speed is based

on the frequency of the incoming power. The best way to change speed is to

somehow change the frequency of the incoming AC waveform. The firmware we

wrote for the PIC 18F series, all 3000 lines of it, accomplished that. I was the only

one on the controls team with any real assembly language experience. I completed

all the course requirements to be a computer engineer

before switching to EE for my super senior year.

This is a picture of the FEC controls team. These five people were tasked with writing

the software that would make our home-grown variable frequency drive make a home

grown induction motor go in circles. VFD is how you change the speed of induction

motors. You cannot just change the voltage into them, as their speed is based

on the frequency of the incoming power. The best way to change speed is to

somehow change the frequency of the incoming AC waveform. The firmware we

wrote for the PIC 18F series, all 3000 lines of it, accomplished that. I was the only

one on the controls team with any real assembly language experience. I completed

all the course requirements to be a computer engineer

before switching to EE for my super senior year.

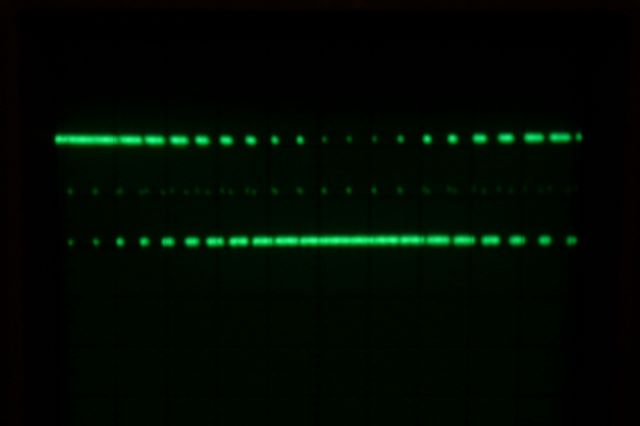

This is what the firmware outputs. This picture is one phase

worth of control signals, that eventually get turned into gating signals for the hex

bridge. If you look at it, you can see that the bright and dark approximates a sine

wave. This photo came out of my digital camera using my personal scope in my apartment.

As you change the speed command to the VFD, the system changes the timing such that

the sine wave approximation goes either faster or slower. These signals are piped

into a bunch of big transistors that turn on and off a high voltage DC source in

alignment with these control signals. By the time this pulse width modulated DC gets through

the inductance of a motor, you have a pretty good looking AC sine wave. We were

using three phase motors and controls, so the control code actually produced three

waveforms like this, all 120 degrees out of phase from the previous.

This is what the firmware outputs. This picture is one phase

worth of control signals, that eventually get turned into gating signals for the hex

bridge. If you look at it, you can see that the bright and dark approximates a sine

wave. This photo came out of my digital camera using my personal scope in my apartment.

As you change the speed command to the VFD, the system changes the timing such that

the sine wave approximation goes either faster or slower. These signals are piped

into a bunch of big transistors that turn on and off a high voltage DC source in

alignment with these control signals. By the time this pulse width modulated DC gets through

the inductance of a motor, you have a pretty good looking AC sine wave. We were

using three phase motors and controls, so the control code actually produced three

waveforms like this, all 120 degrees out of phase from the previous.

This is the first version of the board that the class produced. At the bottom is the

control board, and at the top of that is the inverter board. To make testing easier,

I mounted a plastic sheet over the top with DC inputs, AC outputs, a speed pot

and programming ports. This was the team's first attempt at PCB layout, and it is,

in a word, a disaster. The first time I tried working on this, I was humming circus

calliope music to myself.

All the bypass caps are in a line, the connectors are all in different directions, there

were no test points that are reachable, even when not mounted under the cover. Layout

is extremely

important in motor drives, and we spent more time fooling around with ground bounce

due to poor PCB layout and ground routing then perhaps any other single problem. It was

after the failure of this that I started working on The Cube, so I could have a more

reliable and robust development platform based on the FEC hardware.

This is the first version of the board that the class produced. At the bottom is the

control board, and at the top of that is the inverter board. To make testing easier,

I mounted a plastic sheet over the top with DC inputs, AC outputs, a speed pot

and programming ports. This was the team's first attempt at PCB layout, and it is,

in a word, a disaster. The first time I tried working on this, I was humming circus

calliope music to myself.

All the bypass caps are in a line, the connectors are all in different directions, there

were no test points that are reachable, even when not mounted under the cover. Layout

is extremely

important in motor drives, and we spent more time fooling around with ground bounce

due to poor PCB layout and ground routing then perhaps any other single problem. It was

after the failure of this that I started working on The Cube, so I could have a more

reliable and robust development platform based on the FEC hardware.

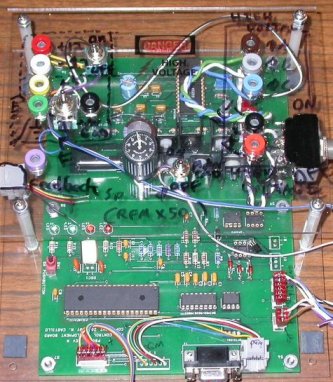

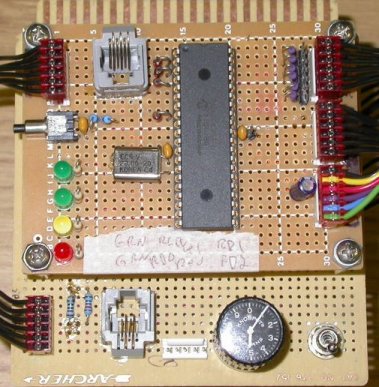

Following the initial two board solution, which was two separate groups' projects

connected by wires, we get to the first "integrated" drive/control. There is also a separate

large PFC, which is actually quite slick looking compared to this.

This was another persons first PCB layout attempt, and looks like a disaster. The only

good way to learn PCB layout is to do it, and then have someone tell you why your

board looks ugly. This particular board did not work, and is actually quite

humorous to look back on now. There are connectors kind of randomly

distributed, bypass caps all over the place, and my favorite, that

little quasi-arc of LED's in the upper right hand corner, complete

with their current limiting resistors kind of all over.

Following the initial two board solution, which was two separate groups' projects

connected by wires, we get to the first "integrated" drive/control. There is also a separate

large PFC, which is actually quite slick looking compared to this.

This was another persons first PCB layout attempt, and looks like a disaster. The only

good way to learn PCB layout is to do it, and then have someone tell you why your

board looks ugly. This particular board did not work, and is actually quite

humorous to look back on now. There are connectors kind of randomly

distributed, bypass caps all over the place, and my favorite, that

little quasi-arc of LED's in the upper right hand corner, complete

with their current limiting resistors kind of all over.

This is what the Rev B board looked like when it was under test. The

importance of having connectors in standard places can be seen by

this picture. When debugging boards, it is very handy to be able to

get to the back side without having huge tangles of things all over

the place. I'm not sure I actually worked on this board much, as at this point

I was dragging in The Cube to do firmware stuff, and leaving this mess to

the hardware guys.

This is what the Rev B board looked like when it was under test. The

importance of having connectors in standard places can be seen by

this picture. When debugging boards, it is very handy to be able to

get to the back side without having huge tangles of things all over

the place. I'm not sure I actually worked on this board much, as at this point

I was dragging in The Cube to do firmware stuff, and leaving this mess to

the hardware guys.

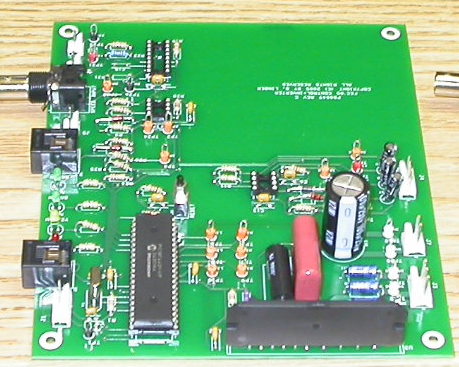

Here's the rev C board. This is an improvement over the rev B boards,

but still not quite there yet- We had trace width issues with this,

and also switched to a different inverter design in rev D which

required a new layout.

Here's the rev C board. This is an improvement over the rev B boards,

but still not quite there yet- We had trace width issues with this,

and also switched to a different inverter design in rev D which

required a new layout.

After getting really annoyed at the Rev C boards, I sat up one night

and laid out another board. This is the rev D board. I attempted to fix

grounding, layout, and isolation issues with this revision. Of course, it

didn't work quite as planned, but at least it looked better. The board

is still very large since

the box, heat sink, and ancillary bits were already designed at this

point. This was my first experience laying out a circuit board. Odd

that as a super senior I would never have done PCB layout before,

but I guess PCB layout is "technician" work and not "engineering"

work. That in spite of the fact that we eventually came to a

consensus that one of the largest problems with this project

was poor signal routing.

After getting really annoyed at the Rev C boards, I sat up one night

and laid out another board. This is the rev D board. I attempted to fix

grounding, layout, and isolation issues with this revision. Of course, it

didn't work quite as planned, but at least it looked better. The board

is still very large since

the box, heat sink, and ancillary bits were already designed at this

point. This was my first experience laying out a circuit board. Odd

that as a super senior I would never have done PCB layout before,

but I guess PCB layout is "technician" work and not "engineering"

work. That in spite of the fact that we eventually came to a

consensus that one of the largest problems with this project

was poor signal routing.

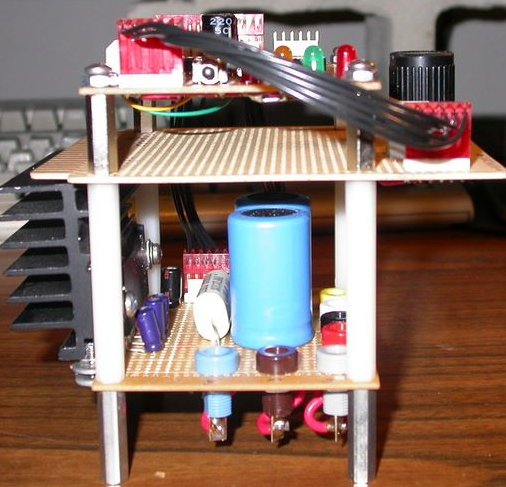

After the debacle trying to debug code on the Rev A board set,

I got fed up and went to my apartment to put together what I

started calling "my hunk of junk". This is a stack of three boards.

The top is the control, middle is the user interface, and bottom

is the inverter. This board stack is what was used to get the

PWM oscilloscope image further up on the page. One of the

main reasons I did this was so that I would have a known-good

thing to whip out when people started saying "It's the software

that is doing this." I could hook this up, put the scope on the

PWM outputs, load the same code and say definitively that no,

in fact, it was not the code that was failing.

After the debacle trying to debug code on the Rev A board set,

I got fed up and went to my apartment to put together what I

started calling "my hunk of junk". This is a stack of three boards.

The top is the control, middle is the user interface, and bottom

is the inverter. This board stack is what was used to get the

PWM oscilloscope image further up on the page. One of the

main reasons I did this was so that I would have a known-good

thing to whip out when people started saying "It's the software

that is doing this." I could hook this up, put the scope on the

PWM outputs, load the same code and say definitively that no,

in fact, it was not the code that was failing.

This is the top view of the cube. At left are the status LEDs,

the reset button, the cable to the user interface board, and the

programming port. Along the bottom is the feedback

optical interrupter feedback (Brian wrote a good hunk

of the feedback code, dubbed "bootleg control" by him),

a speed control, and an on/off switch. The right hand

side has two cables that go down to the inverter board,

carrying PWM and control voltages. The multicolored

cable goes to the power supplies that were used for testing.

This is the top view of the cube. At left are the status LEDs,

the reset button, the cable to the user interface board, and the

programming port. Along the bottom is the feedback

optical interrupter feedback (Brian wrote a good hunk

of the feedback code, dubbed "bootleg control" by him),

a speed control, and an on/off switch. The right hand

side has two cables that go down to the inverter board,

carrying PWM and control voltages. The multicolored

cable goes to the power supplies that were used for testing.

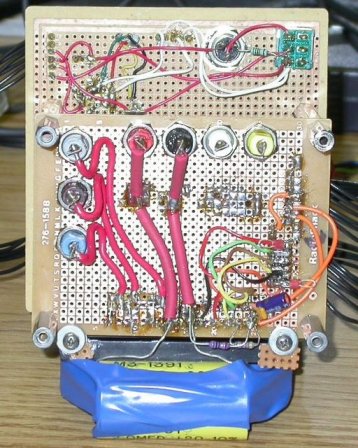

The bottom of the control board. The one big benefit

of wiring up things with these radio shack boards is

that emergency changes are easier than using real PCBs.

The engineer can move wires and slap things down as they

see fit. Of course, the more dense things get, the more

annoying this is, and the easier it is to short things out.

The bottom of the control board. The one big benefit

of wiring up things with these radio shack boards is

that emergency changes are easier than using real PCBs.

The engineer can move wires and slap things down as they

see fit. Of course, the more dense things get, the more

annoying this is, and the easier it is to short things out.

Here's the business end of the cube. DC in at red and

black at the top, AC 3 phase out on the left. The tangle

of wire at the right is the control cable and low voltage

wiring. This worked when ran with an assortment of

bench supplies, but refused to operate when used

with the FEC's PFC and power supply board.

Here's the business end of the cube. DC in at red and

black at the top, AC 3 phase out on the left. The tangle

of wire at the right is the control cable and low voltage

wiring. This worked when ran with an assortment of

bench supplies, but refused to operate when used

with the FEC's PFC and power supply board.

One of the late night lab sessions attempting to

trace out ground bounce issues. The cube was in

the shop, at the right is a Rev D PCB that we are

attempting to get working. This photo pretty much

summarizes the mood I had toward the end of the FEC.

The ground bounce issue only appeared when we were

running any of our boards off the FEC designed power supply.

The FEC designed power supply worked fine when running

load resistors. Definitely the most annoying problem ever.

One of the late night lab sessions attempting to

trace out ground bounce issues. The cube was in

the shop, at the right is a Rev D PCB that we are

attempting to get working. This photo pretty much

summarizes the mood I had toward the end of the FEC.

The ground bounce issue only appeared when we were

running any of our boards off the FEC designed power supply.

The FEC designed power supply worked fine when running

load resistors. Definitely the most annoying problem ever.

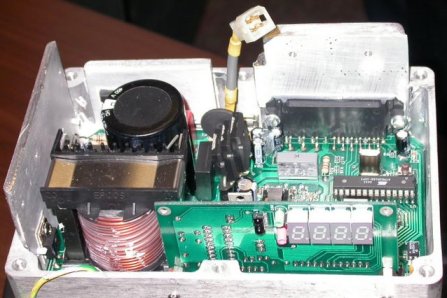

This is the entry that won, from the University of Belgrade,

Serbia. These guys really had their act together, and

totally blasted the other competitors out of the water.

I'm not sure that this device would be as cheap as it

was purported to be, but it was definitely rock

solid, well-built, and well-engineered. They used

the same inverter section that the other teams did,

but managed to pack all their stuff into a nicely

machined aluminum enclosure. They used an

Atmel microcontroller instead of a PIC, and

more commercially available parts. But theirs

worked, and it worked well.

This is the entry that won, from the University of Belgrade,

Serbia. These guys really had their act together, and

totally blasted the other competitors out of the water.

I'm not sure that this device would be as cheap as it

was purported to be, but it was definitely rock

solid, well-built, and well-engineered. They used

the same inverter section that the other teams did,

but managed to pack all their stuff into a nicely

machined aluminum enclosure. They used an

Atmel microcontroller instead of a PIC, and

more commercially available parts. But theirs

worked, and it worked well.

Look at this thing! They had an IR port on the

front and an LED display showing RPMs. I learned

several valid lessons from this experience: First off

all, Serbian engineers from Belgrade are a robust

and intelligent group of people. Next, you show a

lot of confidence in your project if you show up

with nothing but a box containing your prototype.

U of I showed up with a car full of tools and test

equipment. The folks from Belgrade showed up

with a single case containing their finished product,

wrapped in towels and bubble wrap. If you feel you

might need a whole portable electronics bench when

it is time to demo your device, then it is too late.

You are not going to impress anyone at demo time

by pulling out oscilloscopes and tracking down bugs.

That just makes you look unprepared to actually

show the thing off.

Look at this thing! They had an IR port on the

front and an LED display showing RPMs. I learned

several valid lessons from this experience: First off

all, Serbian engineers from Belgrade are a robust

and intelligent group of people. Next, you show a

lot of confidence in your project if you show up

with nothing but a box containing your prototype.

U of I showed up with a car full of tools and test

equipment. The folks from Belgrade showed up

with a single case containing their finished product,

wrapped in towels and bubble wrap. If you feel you

might need a whole portable electronics bench when

it is time to demo your device, then it is too late.

You are not going to impress anyone at demo time

by pulling out oscilloscopes and tracking down bugs.

That just makes you look unprepared to actually

show the thing off.