The Battery Spa @ SmartSpark Energy Systems

To the right is a side view of the four watertanks at SmartSpark Energy Systems.

In the distance is the HotBox described elsewhere on the web page, sitting atop another

hotbox that was built for another project. The tanks on the right are the subject here.

To give a sense of scale, the ladder is a standard 8-foot fiberglass ladder. The

original design goal for this system was to deep-cycle batteries under

controlled conditions while monitoring

the change in their capacities and properties. It was not possible to test

large strings of deep-cycle batteries in hotbox style enclosures, due to the

size required. We took a hint from other companies that test batteries, and instead

decided to use water immersion. I designed a system that consists of

four insulated 300 gallon horse troughs outfitted with spa equipment, insulation,

and a PLC to control charge and discharge. Other engineers at SmartSpark designed

the datalogging system for this.

To the right is a side view of the four watertanks at SmartSpark Energy Systems.

In the distance is the HotBox described elsewhere on the web page, sitting atop another

hotbox that was built for another project. The tanks on the right are the subject here.

To give a sense of scale, the ladder is a standard 8-foot fiberglass ladder. The

original design goal for this system was to deep-cycle batteries under

controlled conditions while monitoring

the change in their capacities and properties. It was not possible to test

large strings of deep-cycle batteries in hotbox style enclosures, due to the

size required. We took a hint from other companies that test batteries, and instead

decided to use water immersion. I designed a system that consists of

four insulated 300 gallon horse troughs outfitted with spa equipment, insulation,

and a PLC to control charge and discharge. Other engineers at SmartSpark designed

the datalogging system for this.

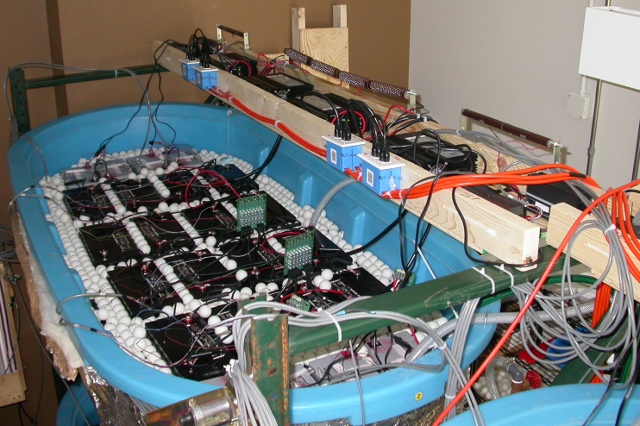

This is a view at the top tank, to illustrate the premise. In the distance are two 2x12

volt gel cell strings undergoing testing. The tanks are oversized for the application,

primarily to give thermal mass to the testing system. The batteries sit up on the bricks

to keep their terminals dry, while keeping a large volume of water in contact with

as much of the battery cases as possible. To the left is a wooden shelf containing

the chargers used for the batteries in this tank. There are some load resistors already

installed at the far left. The cable at right is for the datalogging system, and the

cables at left is all DC charge cable, control cable, or AC power cabling.

This is a view at the top tank, to illustrate the premise. In the distance are two 2x12

volt gel cell strings undergoing testing. The tanks are oversized for the application,

primarily to give thermal mass to the testing system. The batteries sit up on the bricks

to keep their terminals dry, while keeping a large volume of water in contact with

as much of the battery cases as possible. To the left is a wooden shelf containing

the chargers used for the batteries in this tank. There are some load resistors already

installed at the far left. The cable at right is for the datalogging system, and the

cables at left is all DC charge cable, control cable, or AC power cabling.

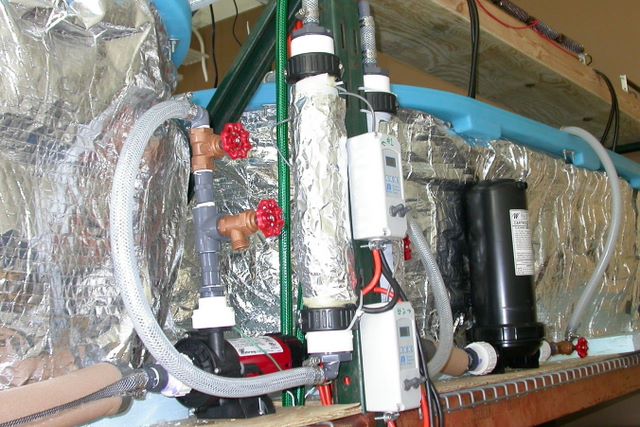

Shown here are two sets of spa equipment of the four total.

The tanks themselves were insulated, as

was as much of the plumbing as was practical. The water is sucked out of the tank

through a strainer in the bottom. It then enters a filter and the suction

inlet of the pump. From the pump the water flows through bypass and drain valves,

followed by the

heater element. Each tank was fitted with a 1.2kW resistive spa heater. They were

on sale at the spa parts warehouse and are actually higher wattage heaters

rated at 240 volts, running at a lower voltage. The water, after passing through

the heaters, goes out the tube at the top and back into the tank at the opposite end

of where it left.

Shown here are two sets of spa equipment of the four total.

The tanks themselves were insulated, as

was as much of the plumbing as was practical. The water is sucked out of the tank

through a strainer in the bottom. It then enters a filter and the suction

inlet of the pump. From the pump the water flows through bypass and drain valves,

followed by the

heater element. Each tank was fitted with a 1.2kW resistive spa heater. They were

on sale at the spa parts warehouse and are actually higher wattage heaters

rated at 240 volts, running at a lower voltage. The water, after passing through

the heaters, goes out the tube at the top and back into the tank at the opposite end

of where it left.

The plastic boxes are the typical Grainger thermostats used elsewhere with additional

switches added to make them double as junction boxes for the pump motor and heater

connections. The two switches are pump and heater on/off. All the AC

wiring in the system is GFCI.

One of the early problems our team had was with heat and water loss due to evaporation.

We were losing about 3 inches of water per day with the heaters running full tilt. To

address this situation, we ordered many pingpong balls and dropped them on the top

of the water. After that fix, evaporative water loss was down to 1/2" per day and

the heaters were running with a 30% duty cycle once the test temperature was reached.

Each morning, the first task I did was to check the water level. I rigged

up a manifold and some valves that run from the sink to each of the tubs, and installed

floating blocks tied to washers to read the water level without having to climb up a

ladder. Topping up the tanks each morning took about five minutes.

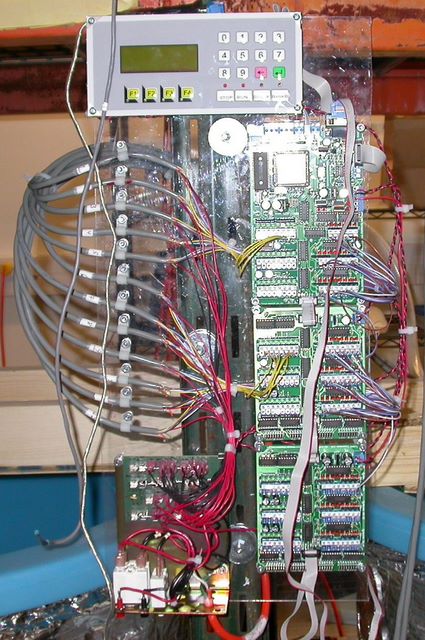

When thinking about the control, I wanted a system that was scalable, reliable,

affordable, and easy to start and stop. Due to the loads involved, we could have had

issues with our lab AC if too many chargers went into bulk mode simulataneously.

In order to prevent this, all 24 charge

circuits were connected to the PLC. The discharge cycles were initiated according

to the PLC's real time clock, and the charge cycles were started only when the

discharge cycle was completed and the PLC agreed to charge.

The LCD screen shows

the time, countdown to the next charge event, and number of cycles completed.

When thinking about the control, I wanted a system that was scalable, reliable,

affordable, and easy to start and stop. Due to the loads involved, we could have had

issues with our lab AC if too many chargers went into bulk mode simulataneously.

In order to prevent this, all 24 charge

circuits were connected to the PLC. The discharge cycles were initiated according

to the PLC's real time clock, and the charge cycles were started only when the

discharge cycle was completed and the PLC agreed to charge.

The LCD screen shows

the time, countdown to the next charge event, and number of cycles completed.

The PLC interfaced to charge boards, which were designed by another engineer at

SmartSpark. This board contained the relays to connect and disconnect

the chargers and loads, and the comparator to signal the PLC when the discharge

cycle was completed. One board was installed per two charge circuits.

One of the valid lessons learned from this project was that if there is already

something out there that does the job, it will probably be cheaper and easier

than doing it yourself. When deciding on the control circuit for this, there

was some interest in whipping out VHDL and writing up a "simple" program,

assembling a PCB, and on and on. This definitely would have worked, but why bother?

SmartSpark wasn't then in the business of building industrial controls. This PLC cost

something like $1200 for the whole setup, which is undoubtedly cheaper

than the engineering time, debugging time, etc of the VHDL solution. The company

even fixed one of the boards for free when I explained a problem!

The bottom of the PLC board contains the power distribution board, which takes 24

volts DC from this big linear surplus supply, puts it through breakers, and sends

it out to the relay boards. Originally the power distribution board was attached to

this big linear supply, where that jagged metal end is on the left of the frame. This

thing weighs a heafty 40 lbs or so, but for about $1.00 per pound for 20 amps of

almost 24 volts, it's quite a bargain compared to other options. Out of frame,

but directly below this is a large "emergency stop" button.

It's big, and red, and quite obvious.

Thankfully we never had to use this, but when pressed, it would interrupt the power

to all the control circuits, which would open all the relays and disconnect the batteries

from the chargers or loads. The E-stop ended up being more like the power switch for

the system.

The bottom of the PLC board contains the power distribution board, which takes 24

volts DC from this big linear surplus supply, puts it through breakers, and sends

it out to the relay boards. Originally the power distribution board was attached to

this big linear supply, where that jagged metal end is on the left of the frame. This

thing weighs a heafty 40 lbs or so, but for about $1.00 per pound for 20 amps of

almost 24 volts, it's quite a bargain compared to other options. Out of frame,

but directly below this is a large "emergency stop" button.

It's big, and red, and quite obvious.

Thankfully we never had to use this, but when pressed, it would interrupt the power

to all the control circuits, which would open all the relays and disconnect the batteries

from the chargers or loads. The E-stop ended up being more like the power switch for

the system.

Lo, the batteries in their lovely watery goodness. In the tank you can

see the floating pingpong balls, keeping the water from evaporating.

This tank contains four strings of 4x sealed batteries, plus 4x additional

strings of 2x sealed batteries, all with different types of equalization

equipment. The wooden shelf over the top holds the load resistors, battery

chargers, and charge switching boards, which were controlled by the PLC

described earlier.

Lo, the batteries in their lovely watery goodness. In the tank you can

see the floating pingpong balls, keeping the water from evaporating.

This tank contains four strings of 4x sealed batteries, plus 4x additional

strings of 2x sealed batteries, all with different types of equalization

equipment. The wooden shelf over the top holds the load resistors, battery

chargers, and charge switching boards, which were controlled by the PLC

described earlier.